When buying a 3D printer, you’ll discover that there are many brands offering different types and varying prices. Before you part with your money, there are some important things to keep in mind.

From price and budget considerations to print quality and technology options, we’ll provide you with impartial and knowledgeable information to help you make an informed choice.

So let’s dive in and explore 10 Things To Keep In Mind Before Purchasing A 3D Printer.

Price and Budget Considerations

When considering purchasing a 3D printer, it’s important to factor in your budget and compare prices of different models. There are plenty of cost-effective options available in the market that offer affordable models without compromising on quality. It’s all about finding budget-friendly choices that provide a good price performance ratio and value for money.

Before making a decision, take the time to research and compare prices from various manufacturers and retailers. Look for deals and discounts that can help you save some money. Keep in mind that while higher-priced printers may have more advanced features, there are also cheaper alternatives that can meet your needs as a beginner or hobbyist.

Consider what you’ll be using the printer for and your level of expertise. If you’re just starting out, there’s no need to invest in an expensive machine right away. Look for entry-level printers like the Ender 3, which offers great value at an affordable price.

Ultimately, finding the right 3D printer within your budget is possible with careful consideration and comparison shopping. By exploring different options and weighing their features against their cost, you can find a model that suits both your needs and wallet.

Printing Technology

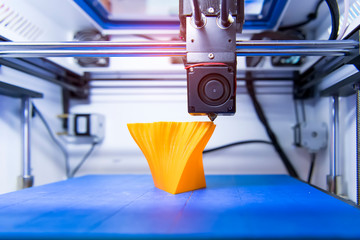

The decision between FDM, SLA, or SLS technology ultimately depends on your printing needs and preferences. Here are some factors to consider when choosing the right printing technology for you:

1. Printing Speed: Different types of 3D printers have varying printing speeds. FDM printers are generally faster compared to SLA and SLS printers. If speed is a priority for you, then an FDM printer may be the better option.

2. Software Options: Consider the software options available for each type of 3D printer. Look for printers that offer user-friendly software with a wide range of features and compatibility with different file formats.

3. Safety Precautions: It’s important to follow safety precautions while using any 3D printer. Ensure proper ventilation in your workspace to minimize exposure to fumes emitted during the printing process. Additionally, take necessary measures to prevent accidents, such as keeping the printer away from flammable materials.

4. Maintenance Tips: Different types of 3D printers require different maintenance procedures. Familiarize yourself with the specific maintenance requirements of each technology before making a decision. Regular cleaning, lubrication, and part replacements are essential for optimal performance and longevity of your printer.

Build Volume and Size Considerations

Consider the size of objects you want to print and evaluate the maximum build volume of a 3D printer before making your decision. The build volume refers to the maximum dimensions that a printer can accommodate for printing objects. It is important to consider this factor because if your desired object is larger than the printer’s build volume, you will not be able to print it in one piece.

When evaluating the build volume, also take into account the dimensions of the printer itself. Make sure that you have enough space in your workspace to accommodate the printer and its necessary accessories. Additionally, consider whether the printer allows for easy expansion or modification in case you have plans for future projects that may require a larger build volume.

Print Quality

Print quality is a crucial factor to consider when choosing a 3D printer. To ensure that your printed objects meet your expectations, here are some key aspects to evaluate:

1. Print resolution: Look for printers with high print resolution capabilities. This determines the level of detail and precision in your prints, resulting in smoother surfaces and finer details.

2. Layer height options: Check if the printer offers a range of layer height options. This allows you to adjust the thickness of each printed layer, giving you control over the balance between speed and quality.

3. Handling complex geometries: Evaluate the printer’s ability to handle complex geometries without compromising on print quality. Some printers may struggle with intricate designs or overhangs, so it’s important to choose one that can handle your specific printing needs.

4. Consistent printing results: Ensure that the printer consistently produces accurate and reliable prints. Look for user reviews and feedback on print consistency, as this will give you an idea of how well the printer performs over time.

Print Speed

When choosing a 3D printer, it’s important to evaluate the printer’s printing speed. The print speed of a 3D printer can have a significant impact on the quality of the final object. Faster prints may compromise on quality, while slower prints may result in higher quality but longer printing times. It’s crucial to find the right balance between speed and quality.

Print speed optimization is a key consideration when using a 3D printer. Adjusting the print speed can help maximize efficiency and achieve the desired level of detail. However, it’s important to note that increasing the print speed too much can lead to issues like poor layer adhesion and reduced accuracy.

To find the optimal print speed for your specific needs, it’s recommended to experiment with different settings and materials. Start by adjusting the print speed in small increments and observing the impact on object quality. Keep in mind that different objects may require different print speeds depending on their complexity and level of detail.

Preferred Material for Beginners

Now that you have learned about the importance of print speed in 3D printing, let’s discuss the preferred material for beginners: PLA (Poly Lactic Acid).

PLA has become a popular choice among beginners due to its numerous advantages. Here are some reasons why PLA is highly recommended:

1. Versatility and Affordability: PLA can be used to print a wide range of objects, from simple prototypes to intricate designs. It is also one of the most affordable filament options available.

2. Safety and Environmental Friendliness: Unlike ABS, PLA does not release harmful fumes during the printing process, making it safer to use. Additionally, PLA is biodegradable and more environmentally friendly compared to other materials.

3. Lower Melting Point: PLA has a lower melting point than ABS, which means it requires less heat during the printing process. This makes it easier to work with for beginners who may not have experience with higher temperature filaments.

4. Comparisons with Other Materials: When compared to other materials like PETG or Nylon, PLA still stands out as a great choice for beginners due to its ease of use and affordability.

To ensure successful prints with PLA, here are some tips:

– Store your PLA filament in an airtight container or bag with desiccant packs.

– Keep your printer’s build plate clean and level.

– Use blue painter’s tape or a glass bed coated with hairspray or glue stick for better adhesion.

– Adjust your print settings for optimal results such as nozzle temperature and cooling fan speed.

Importance of Auto Leveling Printers

Auto-leveling printers, equipped with sensors that ensure a level print bed before printing, offer convenience and stability for 3D printing enthusiasts. These printers are designed to automatically adjust the print bed to ensure a smooth and even surface, eliminating the need for manual leveling.

One of the main advantages of auto-leveling printers is their ease of use. With manual leveling, users have to spend time adjusting the print bed manually, which can be time-consuming and frustrating. Auto-leveling printers eliminate this process, allowing users to start printing quickly and easily.

Another benefit of auto-leveling printers is the improved print quality they provide. A level print bed ensures that the first layer of the print adheres properly, resulting in more accurate prints with better overall quality.

However, it’s important to note that auto-leveling printers may come at a higher price compared to manual leveling printers. Additionally, some users prefer manual leveling as they feel it gives them more control over the printing process.

For those who already own a manual leveling printer but want to enjoy the benefits of auto-leveling technology, there are auto-leveling attachments available in the market. These attachments can be added to existing printers, providing an affordable option for upgrading.

Overall, auto-leveling printers offer convenience and stability for 3D printing enthusiasts. Whether you choose an all-in-one auto-leveling printer or opt for an attachment for your existing printer, these technologies can enhance your 3D printing experience by ensuring a level print bed and improving overall print quality.

Filament Quality and Considerations

To ensure high-quality prints, you should consider the quality of your filament and choose a reliable brand that offers good print results. Here are some important factors to consider when it comes to filament for your 3D printer:

1. Filament storage: Proper storage is crucial to maintain the quality of your filament. Keep it in a dry and sealed container to prevent moisture absorption, which can affect print quality.

2. Filament brands: Choose reputable and well-known brands that have a track record of producing high-quality filaments. Reading reviews from other users can help you make an informed decision.

3. Filament diameter: Make sure the filament diameter matches the specifications of your 3D printer. Using incorrect diameter can lead to printing issues and poor print quality.

4. Filament colors and temperature range: Consider the color options available for your desired filament as well as its temperature range. Different filaments may require different temperatures for optimal printing results.

Understanding the Basics of 3D Printing

If you want to understand the basics of 3D printing, it’s important for you to familiarize yourself with how a 3D printer works and the necessary maintenance tasks involved. To ensure the longevity and efficiency of your printer, regular maintenance is essential. This includes cleaning, part replacements, and software updates. Safety precautions should also be taken into consideration when operating a 3D printer. It is recommended to operate in a well-ventilated room, keep the printer away from fire hazards, and out of reach of children and pets.

When it comes to obtaining 3D models for printing, there are various options available. You can create your own models using software such as Blender, Tinkercad, or Fusion 360. Alternatively, you can download pre-made model blueprints from online sources or join popular 3D printing communities where users share their designs.

Importance of Print Bed Quality

When considering a 3D printer, it’s crucial to prioritize print bed quality because it directly impacts the final print quality. The print bed is where your object will be built layer by layer, so having a high-quality print bed is essential for successful prints. Here are four key factors to consider when evaluating print bed quality:

1. Print Bed Materials: Different materials can be used for the print bed, such as plastic, aluminum, or glass. Glass beds have become popular due to their ease of object removal.

2. Print Bed Leveling: A level print bed ensures that your prints adhere properly and are printed evenly. Look for printers with automatic leveling features or easy manual leveling options.

3. Print Bed Adhesion: Good adhesion between the printed object and the print bed is critical to prevent warping or detachment during printing. Some printers offer specialized surfaces or coatings to improve adhesion.

4. Print Bed Size: Consider the size of objects you plan to print and choose a printer with a suitable print bed size. Larger beds allow for bigger prints while smaller beds may be more compact and cost-effective.

Additionally, some printers offer heated beds, which can help improve adhesion and prevent warping of certain materials like ABS filament.