Are you curious about 3D printing and what it can do for you? Well, you’re in luck! In this article, we’ll dive into the world of 3D printing and explore what exactly a 3D printer is.

From its history to the different technologies used, we’ll cover all the basics.

You’ll also discover the advantages and disadvantages of 3D printing, as well as its applications in various industries.

So, sit back, relax, and let’s get started on your journey to understanding 3D printing.

History of 3D Printing

Now let’s dive into the history of 3D printing and see how it all started.

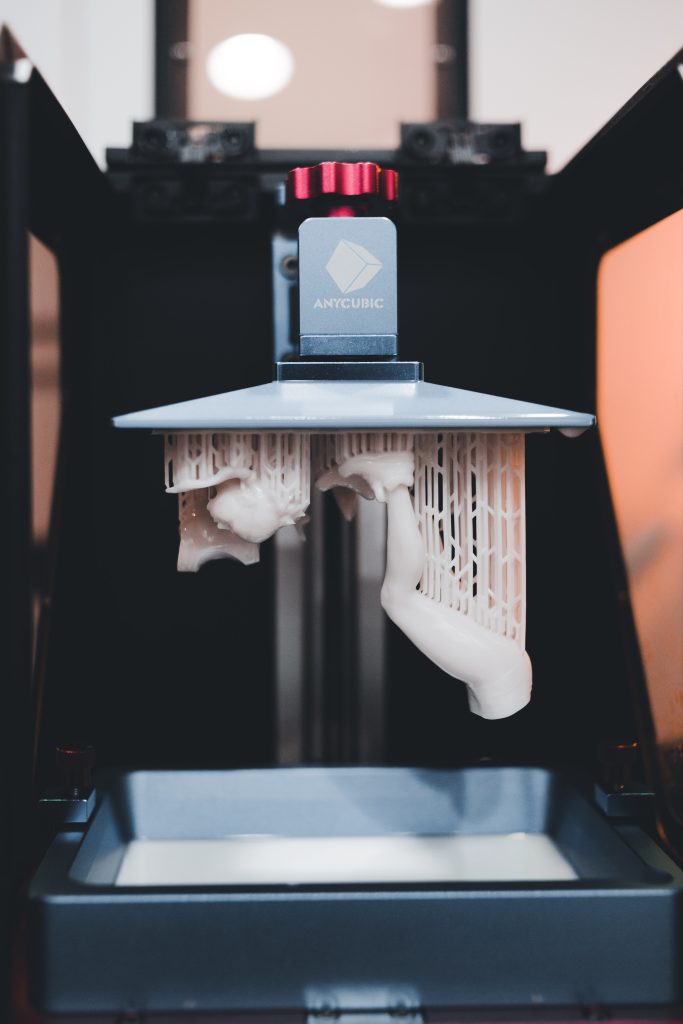

The early pioneers of 3D printing revolutionized the manufacturing industry with their inventions. In the 1980s, Charles Hull invented Stereolithography, which was the first commercial 3D printing technology. This allowed for the creation of solid objects from liquid resin using UV light.

Soon after, other technologies like Selective Laser Sintering and Fused Deposition Modeling were developed. These inventions paved the way for the widespread adoption of 3D printing in various industries.

The impact of 3D printing on the manufacturing industry has been significant. It has allowed for faster prototyping, reduced costs, and increased customization.

Today, 3D printing continues to evolve and disrupt traditional manufacturing processes.

Different 3D Printing Technologies

3D printing technologies utilize various methods to create three-dimensional objects. These methods include material extrusion, binder jetting, and powder bed fusion. Each method offers different advantages and applications in the world of 3D printing.

Material extrusion, also known as Fused Deposition Modeling (FDM), is a commonly used method. It involves melting plastic filament and layering it to create objects. This method is versatile and widely accessible.

Binder jetting, on the other hand, uses a liquid binder to fuse layers of powder together. This method is suitable for producing large and complex parts. It offers the advantage of faster production times and the ability to work with a wide range of materials.

Powder bed fusion technologies, such as Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF), use lasers or binders to fuse layers of powdered material. These methods allow for the production of intricate and precise objects. They are often used in industries such as aerospace and automotive manufacturing.

As 3D printing materials continue to advance, we can expect even more innovative applications and future advancements in this exciting field.

Advantages of 3D Printing

One of the advantages of 3D printing is the cost-effectiveness of creating complex geometries that would be difficult or expensive to produce using traditional manufacturing methods.

With 3D printing, you can customize your designs to meet specific requirements, allowing for greater flexibility and innovation. This customization benefit extends to various industries, such as automotive, aerospace, and medical.

Additionally, 3D printing enables cost-effective production by reducing material waste and eliminating the need for expensive tooling. This makes it an ideal solution for rapid prototyping, allowing for faster iteration and design refinement.

With 3D printing, you can quickly bring your ideas to life and test them before committing to large-scale production.

Overall, the combination of customization benefits, cost-effective production, and rapid prototyping makes 3D printing a valuable tool in modern manufacturing.

Disadvantages of 3D Printing

While 3D printing offers numerous advantages, it is important to consider the limitations and drawbacks of this technology.

One of the main drawbacks is the cost implications. 3D printers can be expensive to purchase and maintain, especially for high-quality and industrial-grade printers.

Additionally, there are post-processing requirements associated with 3D printing. After printing, objects often require additional steps such as cleaning, sanding, or painting to achieve the desired finish.

Another limitation is the accuracy of 3D printing. While advancements have been made, there can still be variations in part precision and dimensional accuracy. This is especially important for industries that require precise measurements and high-quality standards.

It is crucial to weigh these limitations against the advantages of 3D printing when considering its implementation.

Applications in Various Industries

The use of 3D printing technology has revolutionized the construction industry, allowing for the creation of commercially available 3D printed houses and intricate concrete designs.

But the applications of 3D printing extend beyond construction. In the fashion industry, 3D printing has opened up new possibilities for unique and customizable designs. From clothing to accessories, designers can create intricate and innovative pieces using this technology.

In architecture, 3D printing has enabled the creation of complex and sustainable structures, pushing the boundaries of traditional construction methods.

Healthcare has also benefited from 3D printing, with the production of customized prosthetics, implants, and medical devices. This technology has transformed the way healthcare professionals approach patient care, providing personalized solutions that improve quality of life.

3D printing continues to revolutionize various industries, pushing the boundaries of what is possible.

Potential Disruptions in Manufacturing

3D printing technology has the potential to disrupt traditional manufacturing methods. It offers cost-effective production of complex geometries and reduces the need for high volume production. This can have a significant impact on supply chains. 3D printing allows for on-demand production, eliminating the need for large inventories and reducing shipping costs. As a result, more localized production and shorter lead times can be achieved.

The economic implications of 3D printing are also noteworthy. While it can lead to job displacement in certain industries, it also creates new opportunities in design, customization, and maintenance of 3D printers. However, there are regulatory challenges that need to be addressed. These include intellectual property rights and safety regulations for materials used in 3D printing.

Overall, the potential disruptions brought about by 3D printing technology require careful consideration and proactive planning. This is necessary to ensure a smooth transition in the manufacturing landscape.

Safety Considerations and Advancements

When considering safety in 3D printing, it’s important to be aware of advancements in ventilation and extraction systems. Safety regulations have been put in place to ensure the well-being of individuals working with 3D printers.

Ventilation systems play a crucial role in maintaining clean air quality within the printing environment. These systems help to remove harmful fumes and particles that may be emitted during the printing process.

Extraction methods are also important in controlling the release of potentially hazardous substances. By effectively extracting and filtering air, these methods help to minimize the risk of exposure to harmful materials.

It is essential to stay updated on the latest advancements in ventilation and extraction systems to ensure a safe working environment when using 3D printers.

Ongoing Developments in 3D Printing

You should stay informed about the latest advancements in 3D printing technology. Ongoing developments in 3D printing are shaping the future of this revolutionary technology.

One of the key areas of focus is the exploration of new use cases for 3D printing. From healthcare to construction, 3D printing is being applied in various industries to create customized products and prototypes.

Additionally, material advancements are being made to expand the range of materials that can be used in 3D printing, such as metals, ceramics, and even biological materials. These advancements are opening up new possibilities for creating complex and functional objects.

Looking ahead, the future prospects of 3D printing are promising. As technology continues to evolve, we can expect to see even more innovative applications and advancements in the field of 3D printing.