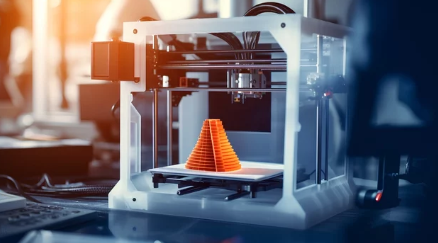

Are you curious about the obstacles faced when printing large-scale 3D objects? This article delves into the challenges that arise and provides insights into overcoming them. From material costs and pre- and post-processing to technology limitations and printer selection, many factors can hinder successful large object printing. However, advancements in materials and technology, alongside increasing adoption of 3D printing, offer hope for a future where large object printing becomes more accessible and cost-effective. Join us as we explore the potential solutions to these challenges.

Cost-Related Challenges in 3D Printing Large Objects

You may face significant cost-related challenges when it comes to 3D printing large objects. Cost analysis is crucial in determining the feasibility of such projects. The cost of materials can be a major factor, as large objects require more material, leading to higher expenses. Material optimization becomes essential in order to minimize waste and reduce costs. Additionally, printing speed is a key consideration, as longer print times can result in higher labor costs. It is important to explore scalability solutions that can increase the efficiency of printing large objects without compromising quality. Post processing techniques also play a role in cost management, as they can add additional expenses. Therefore, it is necessary to evaluate and implement cost-effective post processing methods. By addressing these challenges and finding solutions, such as optimizing materials and streamlining the printing process, the cost of 3D printing large objects can be effectively managed. This will enable businesses and industries to harness the full potential of 3D printing technology in a cost-efficient manner.

Material Limitations in 3D Printing Large Objects

When it comes to 3D printing large objects, one must consider the material limitations that can impact the feasibility and success of the printing process. These limitations include:

1. Material selection: The availability of suitable materials for additive manufacturing can be limited, especially when it comes to large-scale printing. The choice of materials affects factors such as strength, flexibility, and durability of the printed object.

2. Scalability challenges: Printing large objects requires materials that can be efficiently scaled up without compromising quality. Issues such as warping, shrinkage, and inconsistent layer adhesion can arise when printing with certain materials on a larger scale.

3. Printability issues: Some materials may present challenges in terms of their printability. Factors such as viscosity, flowability, and temperature sensitivity can affect the ability to accurately and consistently print large objects.

4. Structural integrity: Large objects require materials with sufficient strength and stability to maintain structural integrity. Weaknesses in the material or the printing process can result in deformations, cracks, or structural failures in the printed object.

To overcome these material limitations, it is important to carefully select materials that are suitable for large-scale printing, optimize printing parameters to ensure proper adhesion and structural integrity, and implement post-processing techniques to enhance the quality and performance of the printed object.

Technology Constraints in 3D Printing Large Objects

To address the challenges mentioned earlier, it is crucial to understand the technology constraints involved in 3D printing large objects. One of the main technology limitations is scalability. While 3D printing has proven to be effective for producing small to medium-sized objects, scaling up to larger sizes presents challenges. Printing speed is another constraint that needs to be considered. As the size of the object increases, the printing time also increases significantly. This can lead to longer production times and reduced efficiency. Size constraints are also a factor to consider. 3D printers have physical limitations in terms of the maximum size of objects they can print.

Material compatibility is another important consideration when printing large objects. Some materials may not be suitable for 3D printing on a large scale, and finding the right materials that can withstand the printing process and maintain structural integrity is crucial. In conclusion, technology constraints such as scalability challenges, printing speed, size constraints, and material compatibility need to be carefully addressed when 3D printing large objects.

Challenges Specific to Industries in 3D Printing Large Objects

Additionally, it is important to consider the specific challenges faced by different industries when it comes to 3D printing large objects.

1. Industrial applications: Industries such as aerospace, automotive, and heavy equipment require the production of large objects with high structural integrity. This poses challenges in terms of ensuring the strength and durability of the printed parts.

2. Scalability challenges: Scaling up the 3D printing process to accommodate large objects can be a complex task. Ensuring consistent quality and dimensional accuracy becomes more challenging as the size of the object increases.

3. Print time optimization: Printing large objects can take a significant amount of time. Optimizing the print time is crucial to improve efficiency and productivity in industrial settings.

4. Material waste reduction: Printing large objects often requires a considerable amount of material, which can result in wastage. Finding ways to minimize material waste is essential for cost-effectiveness and sustainability.

Addressing these challenges in 3D printing large objects for different industries requires a combination of technological advancements, process optimization, and material innovation. By overcoming these challenges, industries can unlock the full potential of 3D printing for large-scale applications, leading to increased efficiency, cost savings, and improved product quality.

Quality and Performance Issues in 3D Printing Large Objects

To ensure the successful production of large 3D printed objects, addressing quality and performance issues is crucial. Dimensional accuracy is one of the main concerns when printing large objects. As the size of the object increases, the likelihood of dimensional errors also increases. This can lead to misalignments and improper fit of parts, affecting the overall functionality of the object. Another challenge is the limited print bed size of 3D printers. Large objects may exceed the maximum build volume of a printer, requiring the object to be printed in multiple parts and assembled later.

This can result in weak points and reduced structural integrity. Surface finish is another important aspect to consider. Large objects may have visible layer lines and rough surfaces, which can affect the aesthetics and usability of the object. Material shrinkage is also a concern when printing large objects. Some materials have a tendency to shrink during cooling, leading to warping and distortion. This can further affect the dimensional accuracy and overall quality of the printed object. Addressing these quality and performance issues requires careful calibration of the printer, optimization of printing parameters, and the use of support structures to minimize warping and ensure proper printing of large objects.

Lack of Expertise and Knowledge in 3D Printing Large Objects

You may face challenges due to a lack of expertise and knowledge in 3D printing large objects. To overcome these challenges, consider the following:

1. Expertise Development: Investing in training programs and workshops can help you develop the necessary skills and knowledge in 3D printing large objects. By staying updated with the latest advancements in printing techniques and materials, you can enhance your expertise in this field.

2. Scalability Solutions: Implementing scalable solutions is crucial to overcome size limitations in 3D printing large objects. This may involve optimizing printing processes, using advanced software for efficient design and slicing, and exploring innovative printing techniques such as multi-material printing or continuous printing.

3. Size Limitations: Understand the size limitations of your 3D printer and work within those constraints. If you require larger objects, consider outsourcing the printing to specialized service providers with equipment capable of handling larger scale projects.

4. Collaboration and Networking: Engage with experts and professionals in the field of 3D printing large objects. Collaborate with them to gain insights, exchange ideas, and learn from their experiences. Networking can provide valuable opportunities for knowledge sharing and expertise development.

Budgetary Limitations in 3D Printing Large Objects

Overcoming budgetary limitations is crucial when it comes to 3D printing large objects. The cost of materials and system equipment can be significant barriers to implementing this technology on a large scale. Therefore, effective budget management and cost reduction strategies are essential for successfully executing 3D printing projects. One approach to address the financial considerations is to explore cost-effective solutions for material costs. This can involve sourcing materials from reliable suppliers at competitive prices or finding alternatives that offer similar performance but at a lower cost. Additionally, optimizing the use of materials through efficient design and minimizing waste can contribute to cost reduction. Another aspect of budgetary limitations is the need for reliable additive manufacturing systems.

Investing in high-quality printers that are capable of producing large objects efficiently and consistently can help avoid costly downtime and maintenance. By carefully managing the budget and implementing cost-effective strategies, businesses can overcome budgetary limitations and leverage the benefits of 3D printing technology for large object production.

Future Prospects and Advancements in 3D Printing Large Objects

As we look ahead to the future, advancements in 3D printing technology for large objects are poised to revolutionize various industries. The following are the key future prospects and advancements in 3D printing large objects:

1. Advancements in materials: With ongoing research and development, there will be a wider range of materials available for 3D printing large objects. This will enable the production of objects with enhanced durability, strength, and flexibility.

2. Scalability: Future advancements will focus on improving the scalability of 3D printing technology for large objects. This means that larger and more complex objects can be printed with greater precision and efficiency.

3. Efficiency: The future of 3D printing large objects lies in improving the speed and efficiency of the printing process. This includes reducing printing time, optimizing material usage, and enhancing post-processing techniques.

4. Applications: As the technology continues to advance, we can expect to see an expansion in the applications of 3D printing for large objects. This includes industries such as aerospace, automotive, construction, and healthcare, where customized and complex objects can be produced more efficiently and cost-effectively.

With these advancements in 3D printing technology for large objects, we can anticipate a future where complex and customized objects can be manufactured with greater efficiency and precision. This will open up new possibilities for industries and pave the way for innovative solutions in various fields.

Challenges in Biomedical Product Fabrication Using 3D Printing Technology

In transitioning from the previous subtopic to the current subtopic, let’s now explore the challenges faced in the fabrication of biomedical products using 3D printing technology. One of the key challenges is the selection and use of biocompatible materials. Biomedical products need to be manufactured with materials that are safe for use in the human body, which presents a limitation in material options. Additionally, achieving layer height accuracy is crucial in biomedical product fabrication to ensure the production of precise and functional parts. This requires careful calibration and maintenance of the 3D printing equipment.

Another challenge is staff re-education. The implementation of 3D printing technology in the biomedical field requires training and re-skilling of staff members to ensure their competency in operating the equipment and understanding the intricacies of the technology.

Furthermore, cyber security issues are a concern in the fabrication of biomedical products using 3D printing technology. As the digital files used in 3D printing can be vulnerable to unauthorized access or manipulation, ensuring the security and integrity of these files is of utmost importance.

Lastly, there are challenges related to patents and copyright. With the increasing use of 3D printing technology, there is a potential for intellectual property infringement. Protecting patents and copyrights becomes crucial to safeguard the rights of innovators and prevent unauthorized replication of their designs. These challenges highlight the complexities involved in the fabrication of biomedical products using 3D printing technology and the need for careful considerations and solutions.

Manufacturing 3D Printed Biomedical Products in Malaysia

To address the challenges discussed in the previous subtopic, let’s now delve into the manufacturing of 3D printed biomedical products in Malaysia. In this context, several challenges arise that need to be overcome for successful production. These challenges include:

1. Customization challenges: One of the key advantages of 3D printing technology is its ability to create customized products. However, in the context of biomedical products, achieving precise customization can be challenging due to the intricate nature of human anatomy and the need for accurate fit and design.

2. Management challenges: Managing the manufacturing process of 3D printed biomedical products involves various aspects such as staff re-education, product pricing, limited guidelines, cyber-security issues, marketing, and patents and copyright. These challenges require effective management strategies to ensure smooth operations and compliance with regulations.

3. Local perspective: Manufacturing 3D printed biomedical products in Malaysia requires a local perspective that takes into account the specific needs and requirements of the Malaysian healthcare system. Understanding the local context is crucial for the successful adoption and implementation of 3D printing technology in the biomedical field.

4. Technological challenges: The production of 3D printed biomedical products involves the use of biocompatible materials and clinical testing, which presents specific technological challenges. These challenges include selecting suitable materials, ensuring mechanical properties and dimensional accuracy, and overcoming limitations in nozzle size distribution and powder agglomeration.

Addressing these challenges is essential for the successful manufacturing of 3D printed biomedical products in Malaysia. By adopting a local perspective, managing operations effectively, and overcoming technological limitations, Malaysia can harness the potential of 3D printing technology to revolutionize the biomedical industry.