Are you ready to dive into the exciting world of FDM technology in 3D printing? Get ready to explore the incredible possibilities that this innovative process offers. With FDM, you can bring your ideas to life with ease and efficiency. From rapid prototyping to manufacturing, this technology has revolutionized various industries. In this article, we will introduce you to the advantages of FDM printing, guide you through the process, and help you choose the right printer for your needs. So let’s get started on this thrilling journey!

Advantages of FDM Technology in 3D Printing

One of the advantages of FDM technology in 3D printing is its cost efficiency compared to other methods. FDM 3D printing offers a more affordable option for beginners and professionals alike in the industry. With FDM printers, you can use a wide range of filament materials, including PLA, ABS, PETG, and more. This versatility allows for greater flexibility in choosing the right material for your project needs. Additionally, FDM technology is widely used in construction due to its ability to create durable and strong parts. Whether you are creating prototypes or end-use products, FDM 3D printing provides accessible and cost-effective solutions that meet the demands of various industries.

The Process of FDM 3D Printing

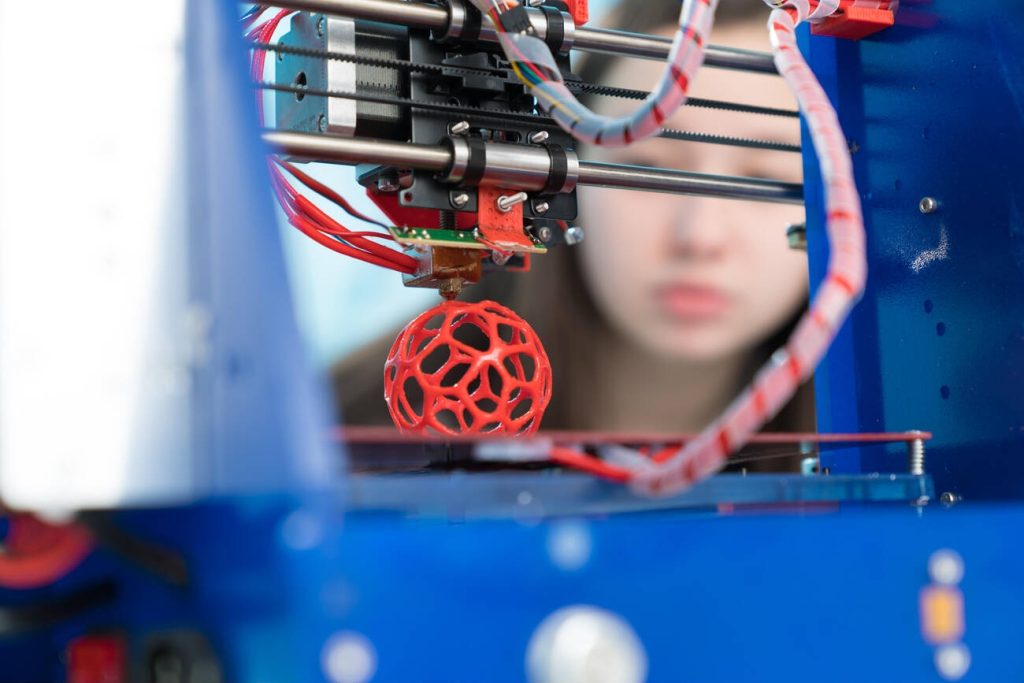

To start the process of FDM 3D printing, you upload a digital design to the 3D printer. Once the design is uploaded, the printer uses different types of filaments such as ABS, PLA, PETG, and PEI to create your desired object. These filaments are melted and fed onto the build platform controlled by a computer. As the nozzle moves across the base, the plastic cools and solidifies layer by layer to form your final product. Depending on your requirements, you can adjust parameters like infill density to determine how solid or hollow you want your object to be. Whether it’s creating images, selling printed items, or even using it in dentistry for dental models and prosthetics, FDM 3D printing offers endless possibilities with its versatile filament options.

Applications of FDM Technology in Various Industries

FDM 3D printing has a wide range of applications across industries such as automotive and consumer goods manufacturing. In addition to these industries, FDM technology is also making significant strides in healthcare and the medical field. The ability to create custom medical devices, prosthetics, and anatomical models using FDM printers has revolutionized patient care. Moreover, FDM 3D printing is being explored for drug delivery systems and tissue engineering, opening up new possibilities in medicine. Not only limited to Earth, FDM technology has even found its way into space exploration, where it is used to manufacture tools and parts on-demand during long-duration missions. If you’re a beginner looking for ideas to explore with FDM 3D printing, consider starting with simple projects like creating personalized phone cases or small household items before venturing into more complex designs.

Choosing the Right FDM 3D Printer for Your Needs

When choosing the right FDM 3D printer for your needs, consider factors such as build volume, printing material, and technical specifications. Here are some things to keep in mind:

- Build Volume: Determine the size of objects you want to print and make sure the printer can accommodate them.

- Printing Material: Consider the type of filament you want to use, such as ABS or PLA, based on your project requirements.

- Technical Specifications: Look at details like extruder temperature, resolution, and printing speed to ensure they meet your expectations.

- Service: Research if there are any local suppliers who offer d printing filament near me and provide support for any potential issues you may encounter.

- Price: Compare different models to find one that fits within your budget.

Technical Specifications and Service Considerations for FDM 3D Printing

Consider researching the extruder temperature, resolution, and printing speed when evaluating technical specifications for FDM 3D printers. These factors play a crucial role in determining the quality and efficiency of your 3D prints. The extruder temperature affects the melting and flow of the filament, while resolution determines the level of detail in your prints. Printing speed directly impacts the time it takes to complete a print job. Additionally, don’t forget to consider service considerations when choosing an FDM 3D printer. Look into warranty terms, service level agreements, and manufacturer support to ensure that you have reliable assistance if any issues arise during your printing process. By thoroughly examining these technical specifications and service considerations, you can make an informed decision when selecting an FDM 3D printer for your needs.

The Future of FDM Technology in 3D Printing

As FDM 3D printing continues to evolve, businesses will be able to adopt this technology more easily and create goods without the need for storage. This opens up exciting possibilities for various industries. Here’s what you can expect in the future:

- D Printing Food: With advancements in FDM technology, we may soon see 3D printers capable of creating edible items, revolutionizing the food industry.

- D Printing Farms: Imagine farms equipped with 3D printers that can produce customized agricultural tools and equipment on demand, increasing efficiency and reducing costs.

- D Printing FDA: As FDM printing becomes more sophisticated, there is potential for it to meet FDA regulations, allowing for the production of medical devices and implants.

- D Printing File Types: The range of file types compatible with FDM printers will expand, enabling users to print a wider variety of designs and models.

- D Printing Infill Patterns: Innovations in infill patterns will enhance strength and reduce material usage, making 3D printed objects even more durable and cost-effective.

New Materials and Longevity in FDM 3D Printing

To maximize the potential of FDM 3D printing, you should explore the development of new materials that offer enhanced properties and longevity. With advancements in technology, new materials can be created to meet specific needs and requirements. For example, materials like woodfill and carbon fiber-infused material can provide added strength and durability to printed objects. Additionally, exploring different filament options such as PLA or ABS can open up a world of possibilities for your prints. By experimenting with various materials, you can achieve desired results for a variety of applications. Whether it’s creating prototypes, functional parts, or even artistic pieces, the right choice of material can make all the difference in achieving successful prints.

| Material | Properties |

|---|---|

| Woodfill | Natural wood-like appearance |

| Carbon fiber-infused | Increased strength and rigidity |

| PLA | Biodegradable |

| ABS | Durable and impact-resistant |

Introduction to FDM 3D Printing and Its Working Principles

Now let’s delve into the world of FDM 3D printing and explore its introduction and working principles. This will give you a better understanding of how this technology operates.

- FDM 3D printing is used for rapid prototyping, allowing for quick creation of physical models.

- The process involves depositing melted filament material layer by layer to build the desired object.

- Digital design files are translated into physical dimensions that guide the printer’s movements.

- Common materials utilized in FDM printing include ABS, PLA, PETG, and PEI.

- To achieve optimal results, various factors such as extruder temperature, resolution, and print speed can be adjusted.

Comparison Between Desktop and Industrial FDM Printers

Desktop and industrial FDM printers have distinct differences in terms of maintenance requirements, efficiency, accuracy, and layer thickness. When it comes to maintenance, desktop printers typically require more frequent attention due to their smaller size and lower build volume. Industrial printers, on the other hand, are designed for heavy-duty use and often come with automated features that reduce the need for manual maintenance. In terms of efficiency, industrial printers are more powerful and capable of producing larger orders at a faster rate compared to desktop models. Additionally, industrial printers tend to offer higher accuracy and smaller layer thickness options, allowing for more precise and detailed prints. Overall, while both types of FDM printers have their advantages, it’s important to consider your specific needs and requirements when choosing between them.

Characteristics and Challenges of FDM 3D Printing

When considering FDM 3D printing, you should be aware of the challenges such as warping and the importance of layer adhesion for strong and durable parts. To help you navigate these challenges, here are a few key points to keep in mind:

- Proper design choices and temperature monitoring can help prevent warping during the printing process.

- Ensuring good layer adhesion is critical for creating parts that can withstand mechanical stress.

- Support structures may be necessary for certain part geometries to maintain structural integrity.

- Experimenting with different materials and adjusting print settings can help optimize your prints.

- Post-processing techniques such as sanding, priming, or epoxy coating can further enhance the appearance and strength of your printed parts.