Are you torn between 3D printing and CNC machining? Wondering which one will give you the best bang for your buck? Well, look no further! In this efficiency showdown, we’ll compare the two manufacturing methods to help you make an informed decision. With 3D printing, you can quickly create complex shapes at a lower cost, but precision might be a challenge. On the other hand, CNC machining ensures high precision and material properties, making it ideal for large-scale production. So let’s dive in and find out which technology suits your needs best!

Advantages of 3D Printing

3D printing allows for the quick production of net shape parts, while CNC machining requires individual setup and programming. This advantage makes 3D printing ideal for a wide range of applications. In healthcare, 3D printing has revolutionized medical procedures by enabling the creation of personalized implants and prosthetics. It has also played a significant role in architecture, allowing architects to create intricate models and prototypes with ease. Furthermore, 3D printing has found its place in education, where it is used to teach students about design thinking and problem-solving skills. The ability to work with various materials is another benefit of 3D printing. From plastics like ABS and PLA to metals like aluminum and titanium, there are endless possibilities for creating functional parts using this technology.

Disadvantages of 3D Printing

To achieve high precision in your parts, you may find it challenging with 3D printing compared to CNC machining. 3D printing has its limitations that can affect the final quality of your parts. One of the challenges in 3D printing is achieving consistent strength in the printed parts. The strength can vary depending on the printing process and material used. Additionally, surface finish in 3D printing may not be as smooth or precise as what can be achieved with CNC machining. Stepped surfaces and visual disruptions are common due to the mechanics of the printing process. While 3D printing offers many advantages, including quick production and customization capabilities, it’s important to consider these limitations when aiming for high precision and surface finish in your parts.

Advantages of CNC Machining

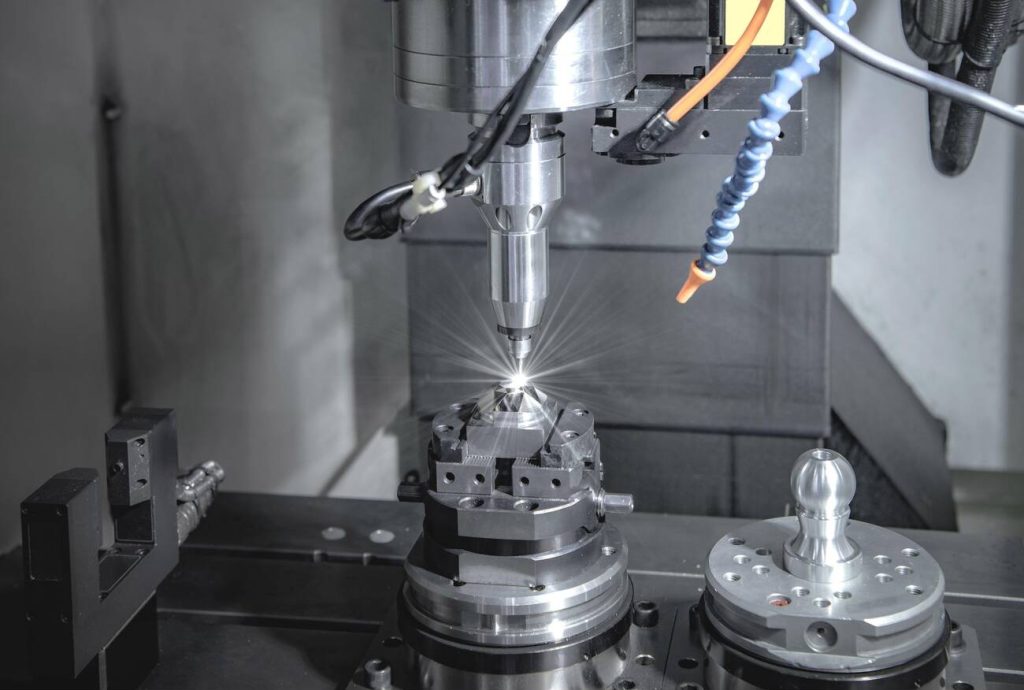

CNC machining offers precise tolerances and the ability to create complex geometries, making it a favorable choice for many manufacturing applications. With CNC machining, you can achieve high precision in your parts, ensuring that they meet the exact specifications required. Additionally, CNC machining provides excellent surface finish, resulting in smooth and polished surfaces that are visually appealing.

Another advantage of CNC machining is the wide range of material options available. Whether you need to work with metals like aluminum or stainless steel, or plastics like ABS or Nylon, CNC machining can handle it all. This versatility allows you to choose the most suitable material for your specific application.

Furthermore, CNC machining is well-suited for mass production due to its efficiency and consistency. It can produce large quantities of parts with consistent quality and accuracy, making it ideal for meeting high-demand production requirements.

Lastly, CNC machining excels at handling complexity. It can create intricate geometries and features with ease, allowing you to manufacture even the most complex designs without compromising on precision or quality.

Comparisons and Alternatives

When considering manufacturing options, it is important to compare and explore alternative techniques. In the case of 3D printing and CNC machining, there are pros and cons to consider. For material selection, CNC machining offers a wider range of options including metals like aluminum, stainless steel, and titanium. On the other hand, 3D printing primarily focuses on plastics but is expanding into metal printing as well. Cost analysis is another factor to consider. While 3D printing is generally cheaper for small volumes, CNC machining may be more economical for medium to high-volume production. Design considerations vary as well – CNC machining allows for complex geometries with tight tolerances while 3D printing excels in creating highly complex designs with topology-optimized structures. Ultimately, the choice between these two methods depends on the specific application requirements and desired outcomes.

Factors to Consider When Choosing Manufacturing Technology

One important factor to consider when choosing manufacturing technology is the complexity of the part. The more complex the part, the more suitable 3D printing becomes. When making this decision, there are several factors you should take into account:

- Cost considerations:

- 3D printing is generally cheaper than CNC machining for small volumes.

- CNC machining can be more cost-effective for medium to high-volume production.

- Turnaround time:

- 3D printing offers fast turnaround times due to its additive nature.

- CNC machining may require individual setup and programming, resulting in longer lead times.

- Material selection:

- Consider the materials that each technology can work with.

- Parts requiring materials that are difficult to machine may be better suited for 3D printing.

- Part complexity:

- CNC machining can handle complex parts with tight tolerances and sharp edges.

- 3D printing is ideal for highly complex geometries and topology-optimized designs.

- Post processing techniques:

- Both technologies may require post-processing techniques to improve dimensional accuracy and surface finish.

Number of Parts and Technology Selection

Consider the number of parts needed when deciding between 3D printing and CNC machining. Cost considerations, scalability options, material compatibility, time efficiency, and quality control measures are important factors to take into account. If you have a small quantity of parts (fewer than 10 identical pieces), 3D printing is ideal due to its fast turnaround time and lower cost for small volumes. On the other hand, if you require medium to high-volume production, CNC machining is more suitable. CNC machining also offers a wider range of material options compared to 3D printing. Additionally, CNC machining provides higher precision and tighter tolerances compared to 3D printing. Consider your specific requirements and explore alternative options before making a decision on which technology to choose for manufacturing your parts.

Dimensional Accuracy Comparison

To ensure dimensional accuracy, you’ll find that CNC machining offers tight tolerances and excellent repeatability. When comparing dimensional accuracy between CNC machining and 3D printing, there are a few key factors to consider:

- Stepped surfaces: CNC machining produces smooth and precise surfaces without any visible steps. In contrast, 3D printed parts may have stepped surfaces due to the layer-by-layer build process.

- Visual disruptions: While CNC machining can achieve a high-quality surface finish, 3D printed parts may exhibit visual disruptions such as layer lines on curved surfaces.

In terms of dimensional accuracy, CNC machining is generally superior to 3D printing. However, it’s important to note that industrial-grade 3D printers can produce parts with good tolerances. For critical dimensions or tighter clearances, 3D printed parts can be oversized and then machined for precision. Additionally, post-processing techniques can be applied to improve the surface finish of both CNC machined and 3D printed parts.

Comparing Materials for Machining and Printing

When comparing materials for machining and printing, it’s important to note that CNC machining primarily works with metals while 3D printing focuses on plastics, but is expanding to include metal printing. Each process has its own limitations and capabilities when it comes to material selection. To compare the two, let’s take a look at a table showcasing some common materials used in both CNC machining and 3D printing:

| CNC Machining | 3D Printing |

|---|---|

| ABS | PLA |

| Nylon | ABS |

| Polycarbonate | Nylon |

| Aluminum | ULTEM |

| Stainless Steel | Aluminum |

As you can see, there is some overlap in the materials used, but each process has its own unique set of compatible materials. When selecting a manufacturing technology, considering the material compatibility is crucial in achieving desired results. Keep in mind any machining limitations or printing capabilities specific to the chosen material.

Manufacturing Complex Parts

Now that you understand the differences between 3D printing and CNC machining, let’s dive into the topic of manufacturing complex parts. This is an important consideration when choosing a manufacturing technology because some parts require intricate geometries and high levels of complexity.

In terms of geometric complexity, 3D printing has a clear advantage over CNC machining. With additive manufacturing, you can easily create highly complex designs and topology-optimized parts that would be challenging to produce using traditional methods. Some 3D printing technologies even allow for the creation of intricate geometries without the need for support structures.

However, it’s worth noting that 3D printing does have its limitations. Build volume can be a constraint in certain technologies like SLS and DMLS, while even larger build volume technologies like FDM cannot compete with CNC machining in terms of size limitations.

When it comes to material compatibility, both 3D printing and CNC machining offer a wide range of options. However, there are some materials that are difficult to machine but can be easily 3D printed. On the other hand, CNC machining allows you to work with engineering materials and deliver their full properties.

In terms of ease of use, 3D printing takes the lead. Once you’ve prepared the file and started the print job, you can leave it unattended until completion. In contrast, CNC machining requires skilled operators who need to choose tools, cutting paths, and perform post-processing techniques.

Overall, when considering manufacturing complex parts, factors such as geometric complexity, build volume limitations, material compatibility, and ease of use should all be taken into account. Both 3D printing and CNC machining have their strengths in this area; it ultimately depends on your specific requirements and priorities.

Manufacturing Techniques

Both 3D printing and CNC machining utilize a variety of materials to create finished parts. In terms of advantages, 3D printing offers net shape parts quickly and at a lower cost compared to CNC machining. It is also ideal for producing complex geometries and intricate details. On the other hand, CNC machining uses engineering materials and delivers precise tolerances, making it suitable for high-volume production and achieving higher precision than 3D printing. When considering complexity, both technologies can handle complex parts, but 3D printing excels in highly complex geometries and topology-optimized designs. Manufacturing technology selection should take into account factors such as complexity, cost, turnaround time, material properties, part geometry, and alternative options like injection molding or laser cutting. Finally, post-processing techniques can be applied to improve dimensional accuracy and surface finish for both 3D printing and CNC machining.