With 3D printing, you can unlock a whole new realm of design possibilities. This technology allows you to quickly create non-final versions of products and test your design ideas in a cost-effective manner.

The flexibility and ease of iteration offered by 3D printing make it an ideal choice for rapid prototyping. Whether you choose to use 3D printing services or invest in your own printer, you’ll have the freedom to experiment and iterate your prototypes with ease.

The Basics of Rapid Prototyping With 3D Printing

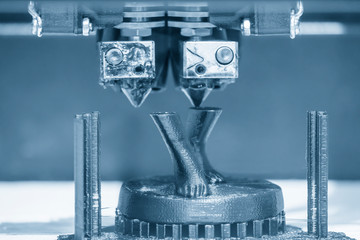

Rapid prototyping with 3D printing allows for quick iterations and modifications of designs, providing flexibility in varying the physical properties of prototypes. This process utilizes rapid prototyping 3D printers to create tangible representations of digital designs. The combination of rapid prototyping and 3D printing offers numerous benefits for prototype development.

By utilizing rapid prototyping with 3D printing, designers can speed up the creation, testing, and refinement processes. Traditional manufacturing methods often involve lengthy lead times and high costs for creating prototypes. However, with 3D printing, designers can produce new iterations within hours or overnight.

The ability to easily modify the digital 3D model allows for faster improvements and adjustments during the prototyping phase. Additionally, different materials can be used to vary properties such as mechanical strength, temperature resistance, and color.

Furthermore, rapid prototyping with 3D printing is a cost-effective solution compared to traditional manufacturing methods for small batch or one-off prototypes. The lower costs associated with 3D printing enable businesses to create more iterations and prevent the release of untested products.

Advantages of 3D Printing in Design Flexibility

Rapid 3d prototyping printing offers numerous advantages in terms of flexibility and allows for the creation of intricate and customized designs. Here are three key benefits of using 3D printing for rapid prototyping:

Rapid prototyping with a 3D printer

3D printing technology enables the quick production of prototypes, allowing you to iterate and refine your design ideas at a faster pace. With traditional manufacturing methods, creating prototypes can be time-consuming and costly, but with 3D printing, you can bring your concepts to life in a matter of hours or days.

Enhanced design freedom:

When it comes to prototyping in 3D printing, you have the freedom to experiment and explore complex geometries that may not be feasible with other manufacturing techniques. This level of design flexibility opens up new possibilities for innovation and creativity in product development.

Customization for prototypes

With 3D printing, you can easily customize your prototypes according to specific requirements or user preferences. Whether it’s adjusting the size, shape, or material properties of the prototype, 3D printing allows for easy modifications without the need for expensive tooling or molds.

Unlocking the Power of Rapid Prototyping

You can take advantage of the efficiency and cost-effectiveness of rapid prototyping by integrating a 3D printer into your product development process. With 3D printing, you have the power to transform your digital designs into tangible prototypes quickly and accurately.

The technology allows for the creation of complex geometries and intricate internal structures that were previously difficult or even impossible to achieve with traditional manufacturing methods.

By using 3d printing for prototypes, you can significantly reduce lead times and costs compared to conventional production techniques. The ability to print directly from digital designs eliminates the need for expensive tooling or molds, making it an ideal solution for small batch or one-off prototypes. Additionally, 3D printing enables faster iterations and innovation cycles, allowing you to refine your designs based on feedback and testing.

The flexibility of prototype 3d print extends beyond just speed and cost savings. You have full control over the physical properties of your prototypes, including strength, rigidity, temperature resistance, and even color. This versatility opens up new possibilities for experimentation and optimization in your product development process.

Incorporating a 3D printer into your workflow empowers you to unlock the power of rapid prototyping. It accelerates your design iteration process, enhances design flexibility, reduces costs, and ultimately leads to better products in less time. Embrace the potential that comes with integrating 3D printing into your product development process today.

Exploring the Possibilities of 3D Printing in Manufacturing

Take a moment to explore how 3D printing can revolutionize the manufacturing industry by enabling new production methods and designs.

Enhanced Design Flexibility

With 3D printing, manufacturers can create complex geometries and intricate internal structures that were previously impossible with traditional manufacturing methods. This opens up a whole new world of design possibilities, allowing for the production of unique and customized products tailored to individual needs and preferences.

Rapid Prototyping and Iteration

The speed at which prototypes can be created and refined is significantly accelerated with 3D printing. Direct printing from digital designs reduces lead times and costs compared to traditional methods, enabling faster product development cycles and better designs. More iterations can be made in less time, leading to faster innovation.

Environmental Benefits

By minimizing material wastage through additive processes, 3D printing reduces environmental impact compared to traditional manufacturing. Optimization of designs and the use of required materials further reduce costs and carbon emissions. Additionally, on-demand manufacturing optimizes supply chains, reducing inventory costs.

With its unparalleled design freedom, rapid prototyping 3d printing capabilities, customizable manufacturing options, and environmental benefits, 3D printing has the potential to transform the manufacturing industry as we know it. By embracing this technology, manufacturers can unlock new dimensions of production possibilities while staying competitive in today’s fast-paced market.

Maximizing Efficiency With 3D Printing for Rapid Prototyping

Maximizing efficiency is crucial when utilizing 3D printing for rapid prototyping, as it allows for faster iterations and improved product development cycles. By leveraging the capabilities of 3D printing technology, you can streamline your prototyping process and achieve significant time and cost savings.

- One key advantage of 3D printing in rapid prototyping is its ability to quickly produce physical prototypes directly from digital designs. This eliminates the need for traditional manufacturing methods, such as CNC machining or injection molding, which often involve longer lead times and higher costs.

- With 3D printing, you can design a prototype during the day, print it overnight, and have it ready for testing the next morning.

- Moreover, 3D printing enables easy iteration and modification of designs. You can make changes to your digital model and print a new prototype within hours or even minutes. This flexibility allows you to refine your product design based on feedback and testing results rapidly.

- Additionally, 3D printing offers versatility in material selection. Depending on your specific requirements, you can choose from a wide range of materials with different properties like strength, rigidity, or temperature resistance. This versatility empowers you to test different iterations with varying material characteristics without the need for costly tooling changes.

Harnessing the Potential of 3D Printing for Custom Manufacturing

Harnessing the potential of 3D printing allows for the production of customized objects with intricate details and increased design flexibility. Here are three key ways in which this technology is transforming the world of manufacturing:

Tailored Production

With 3D printing, you can create products that are uniquely tailored to individual needs and preferences. This opens up new possibilities for customization on a mass scale, offering consumers personalized solutions like never before.

Complex Geometries

Traditional manufacturing methods often have limitations when it comes to producing complex geometries and intricate internal structures. But with 3D printing, these barriers are broken down. You can now print complex parts as a single piece, reducing assembly time and potential points of failure.

Enhanced Design Freedom

3D printing offers unparalleled design freedom, allowing you to explore innovative designs without constraints imposed by traditional manufacturing processes. You can push the boundaries of creativity and create objects with intricate details that were previously impossible to achieve.

Implementing Rapid Prototyping With 3D Printing: Tips and Tricks

When implementing rapid prototyping with 3D printing, you can make the process more efficient by utilizing software that streamlines the workflow and enables accurate parts for better design decisions. Software plays a crucial role in optimizing the entire process of rapid prototyping with 3D printing. It helps in creating digital designs, preparing them for printing, and managing the printing workflow.

GrabCAD Print

This software simplifies the transition from CAD to 3D printed parts by providing a user-friendly interface and powerful features. It allows you to import your designs directly from CAD software and easily prepare them for printing. With GrabCAD Print, you can also analyze your models for potential issues before sending them to the printer, ensuring accurate and high-quality prints.

GrabCAD Shop

This software saves time and increases productivity by facilitating collaboration among team members involved in 3D printing work orders. It provides a centralized platform where designers, engineers, and other stakeholders can request prints, track progress, and communicate effectively.