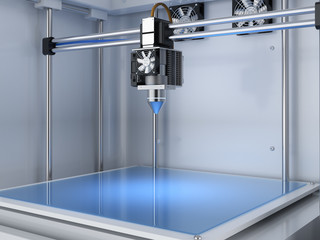

3D printing technology has revolutionized manufacturing and design processes, allowing for the creation of complex objects with ease. Achieving high-quality prints is a top priority in the world of 3D printing, and print tolerance plays a crucial role in this pursuit. In this blog post, we will explore the concept of print tolerance, its significance in achieving precise prints, and the immense potential it holds for the future of 3D printing.

Understanding Print Tolerance

Understanding Print Tolerance is crucial in achieving high-quality 3D prints. Print tolerance refers to the acceptable deviation from the intended dimensions of a 3D printed object. In other words, it measures how closely the final print matches the design specifications.

Print tolerance is expressed as a numerical value or percentage that represents the maximum allowable variation from the desired dimensions. For example, a print tolerance of ±0.1 mm means that the actual dimensions of the printed object can deviate by up to 0.1 mm from the intended measurements.

How accurate are 3d printers? Several factors influence print tolerance in 3D printing.

- The choice of materials plays a significant role, as different materials have varying properties and behaviors during the printing process. Some materials may shrink or expand more than others when cooling, affecting the final dimensions of the printed object. Therefore, selecting materials with known and consistent properties can help achieve tighter FDM tolerances.

- 3D printer tolerance settings also impact print tolerance. Parameters such as nozzle size, layer height, and printing speed can affect the accuracy and precision of the printed object. Fine-tuning these settings and ensuring proper calibration of precision 3D printers can improve print tolerance and overall print quality.

- The complexity of the design is another factor to consider. Intricate or complex designs with overhangs or unsupported structures may require different print settings or additional support structures to maintain the desired tolerance. Design considerations should be made to optimize printability and minimize potential errors or deviations in the final print.

- Choosing the appropriate print tolerance for a given project is essential. It depends on the specific requirements of the object and its intended use. Functional parts, such as mechanical components, may require tighter tolerance of 3d printing to ensure proper fit and functionality. On the other hand, artistic models or decorative objects may allow for slightly looser tolerances to prioritize aesthetics.

Print Tolerance and Dimensional Accuracy

Print tolerance plays a vital role in ensuring the dimensional accuracy of 3D printed objects. When tolerances are too loose, the printed object may have deviations from the intended dimensions. This can result in poor fit between components or parts, compromising the functionality of the final product. On the other hand, achieving tight print tolerances can be challenging and may lead to failed prints due to issues such as warping or distortion.

By carefully selecting the appropriate print tolerance, designers and manufacturers can ensure that their 3D printed objects meet the required dimensional specifications. This is particularly important in industries such as aerospace or medical, where precision and accuracy are critical.

Print Tolerance and Surface Finish

In addition to dimensional accuracy, print tolerance also has a significant impact on the surface finish of 3D printed objects. Tighter tolerances generally result in smoother surfaces, as there is less room for variations or imperfections. This is particularly important for applications where a high-quality surface finish is desired, such as consumer products or artistic designs.

Achieving precise print tolerances allows for the creation of intricate sculptures and detailed designs that were once thought impossible. Artists and designers can leverage the capabilities of 3D printing accuracy to produce visually stunning objects with intricate details. These fine details are made possible by the ability to achieve tight tolerances, resulting in smooth surfaces and accurate reproductions of complex shapes.

Print Tolerance and Details

Print tolerance also affects the level of detail that can be achieved in 3D printed objects. Tight tolerances enable the recreation of fine details with high fidelity, while looser tolerances may result in loss of delicate features or reduced sharpness.

In industries such as jewelry design or miniatures, the ability to accurately reproduce tiny details is essential. Precise print tolerances allow for the creation of intricate patterns, textures, and complex geometries that enhance the visual appeal of the final printed objects.

Techniques to Improve Print Tolerance

Calibrating and Fine-tuning 3D Printers

Calibrating and fine-tuning an accurate 3D printer is a crucial technique for improving print tolerance. This process involves adjusting various parameters to ensure the printer’s accuracy and precision. Here are some key aspects of printer calibration that can help enhance print tolerance:

Bed Leveling

Proper bed leveling is essential for ensuring an even and flat printing surface. A leveled bed helps maintain consistent first-layer adhesion, reducing the chances of warping or shifting during the printing process.

Nozzle Height

Adjusting the nozzle height or “Z-axis offset” ensures the optimal distance between the nozzle and the print bed. This adjustment affects the first layer’s accuracy and adherence, which is crucial for maintaining dimensional accuracy throughout the print.

Extrusion Rate

Fine-tuning the extrusion rate ensures that the proper amount of filament is being deposited. Adjusting the flow rate can help achieve the desired print dimensions and prevent over or under-extrusion issues.

Choosing the Right Materials and Filaments

The choice of materials and filaments also has a significant impact on print tolerance. Different materials have varying thermal properties, shrinkage rates, and behaviors during the cooling process. Consider the following factors when selecting materials to improve print tolerance:

Shrinkage Rates

Some materials, such as certain types of plastics, may experience shrinkage as they cool after being extruded. Understanding the shrinkage characteristics of the chosen material and compensating for it in the design can help achieve tighter tolerances.

Thermal Properties

Materials with better thermal stability and low coefficients of thermal expansion tend to exhibit less dimensional variation during the printing process. Choosing materials with these properties can contribute to improved print tolerance.

Design Considerations for Print Tolerance Optimization

Design considerations can play a vital role in optimizing print tolerance, especially for complex geometries or challenging prints. Here are a few techniques to consider:

Adding Supports

For prints with overhangs or complex geometries, adding supports can help maintain the desired tolerances. Supports provide stability during the printing process and prevent deformations or sagging.

Modifying Overhangs

Designing overhangs at appropriate angles can minimize the need for supports and reduce potential print errors. By optimizing the design for self-supporting structures, the risk of deviations from the intended dimensions can be reduced.

Real-world Applications of High Print Tolerance

Industrial Applications

High print tolerance has numerous real-world applications in various industries. In industrial settings, precise print tolerances are essential for prototyping and manufacturing processes. Here are a few examples:

Functional Prototyping

High print tolerance allows for the creation of accurate prototypes that closely resemble the final product. This is particularly valuable in industries such as automotive and aerospace, where functional prototypes are extensively tested for performance and fit before production.

Customized Manufacturing

With tight tolerances, 3D printing precision enables the production of custom parts and components with high precision. This is beneficial in industries like healthcare, where personalized medical devices or implants need to perfectly fit an individual’s unique anatomy.

Jigs and Fixtures

High print tolerance is crucial for creating jigs, fixtures, and tooling in manufacturing processes. These tools must have precise dimensions and tolerances to ensure proper assembly, alignment, and functionality in production environments.

Medical Applications

In the medical field, high print tolerance plays a significant role in advancing healthcare technologies. Some notable applications include:

Surgical Guides and Implants

3D printing with high tolerance allows for the creation of surgical guides that assist surgeons in performing complex procedures with accuracy. Additionally, customized implants can be manufactured with precise tolerances to ensure a perfect fit for patients.

Biofabrication and Tissue Engineering

High print tolerance enables the creation of scaffolds with accurate architectures, where cells can be embedded precisely according to design specifications. This is vital for tissue engineering applications, where the goal is to develop functional living tissues or organs.

Artistic and Design Applications

In the artistic realm, high print tolerance opens up new possibilities for creative expression. Some applications include:

Intricate Sculptures

Fine-tuned tolerances allow artists to create intricate sculptures with complex designs and delicate details. Printing with high tolerance ensures that every fine feature and texture is accurately reproduced, resulting in visually stunning art pieces.

Detailed Designs

Whether it’s jewelry, decorative objects, or architectural models, high print tolerance enables the production of intricate and detailed designs. This level of precision allows artists and designers to bring their visions to life with exceptional accuracy and quality.

Future Trends and Innovations in Print Tolerance

As technology advances, there is a continuous drive to improve print tolerance further. Emerging technologies are being explored to enhance accuracy and precision in 3D printing. Advancements in material science and the development of new filaments hold promise for achieving enhanced tolerances. Additionally, advancements in hardware and software are being made to improve the overall printing process. For example, the use of high-performance polymers, such as PEEK, can contribute to achieving tighter tolerances and improved mechanical properties in 3D prints.

Print tolerance is a critical factor in achieving high-quality 3D prints with precision and accuracy. Understanding the concept of print tolerance, its impact on print quality, and implementing techniques to improve tolerance is essential for harnessing the full potential of 3D printing. By embracing and exploring the possibilities of fine-tuned tolerances, individuals and industries can unlock limitless opportunities for innovation and creativity in the world of 3D printing.