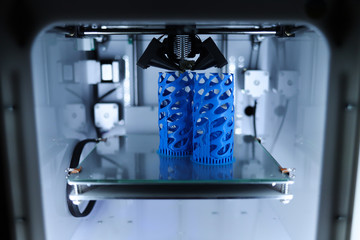

The world of 3D printing is vast and varied, with numerous technologies each offering unique capabilities. Among these technologies, PolyJet 3D printing has emerged as a game-changer due to its unmatched precision and versatility. This blog post will introduce you to the world of PolyJet and compare it with other prominent 3D printing technologies.

Understanding PolyJet 3D Printing

PolyJet is a proprietary technology developed by Stratasys that works by jetting layers of liquid photopolymer onto a build tray. These layers are then instantly cured by ultraviolet (UV) light, forming precise, high-resolution parts.

The key advantages of PolyJet include its ability to print in multiple materials and colors simultaneously, its high level of detail, and its smooth surface finishes. This makes PolyJet particularly beneficial for applications requiring intricate details or varied material properties within the same part.

Comparison with Other 3D Printing Technologies

Stereolithography (SLA)

Stereolithography or SLA is one of the earliest methods of 3D printing and works by using a UV laser to cure liquid resin. The process involves the UV laser tracing the cross-section of each layer on the surface of the liquid resin, solidifying it into a hardened plastic. This method can be slower than PolyJet because it cures one point at a time.

While SLA is known for its excellent surface quality and high level of detail, it may not achieve the same level of detail as PolyJet, especially when printing very complex geometries or assemblies with multiple materials. Despite this, it remains a popular choice for applications that require smooth surfaces, like creating master patterns for vacuum casting.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is another common 3D printing technology. It builds parts by extruding a thermoplastic filament, which is heated to its melting point and then extruded, layer by layer, to create a three-dimensional object.

FDM’s strength lies in its ability to use a variety of thermoplastic materials, resulting in parts that are often stronger and more durable than those made with other 3D printing technologies. This makes FDM ideal for functional prototypes, end-use parts, and manufacturing aids. However, compared to PolyJet, FDM can lack in resolution and may not offer the smooth surface finishes, particularly for complex, intricate designs.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses a high-power laser to fuse small particles of polymer powder. The laser selectively fuses the powdered material by scanning the cross-sections (or layers) generated by the 3D modeling program on the surface of a powder bed.

SLS stands out for its ability to create complex geometries and moving parts in one piece, without the need for support structures. This gives designers more freedom in their designs. However, when compared to PolyJet, SLS might not achieve the same level of detail or surface smoothness, especially for designs that require a high level of detail or smooth surfaces.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is a type of vat polymerization that uses a digital light projector screen to cure the resin layer all at once, making it faster than technologies like SLA that cure one point at a time.

DLP can achieve excellent resolution and surface finish, making it suitable for detailed prototypes and models. However, it often lacks the multi-material capabilities that PolyJet offers. While DLP can use a variety of resins, including flexible, tough, castable, and high-temperature resins, it typically cannot print multiple materials in one job.

Each 3D printing technology has its strengths and ideal applications. While PolyJet excels in detail, surface finish, and multi-material capabilities, other technologies like SLA, FDM, SLS, and DLP also offer unique advantages.

Applications of PolyJet in Various Industries

Applications of PolyJet in the Automotive Industry

The automotive industry has been an early adopter of 3D printing technologies due to the need for rapid prototyping and complex part design. PolyJet is particularly favored in this sector due to its ability to create detailed, multi-material prototypes quickly.

Car manufacturers use PolyJet to produce highly accurate, realistic prototypes of car parts, from small components like knobs and switches to larger parts like dashboards and bumpers. The technology’s capability to print in multiple materials and colors simultaneously allows for the creation of intricate, full-color models that can be used for design verification, testing, and presentations.

Applications of PolyJet in the Aerospace Industry

In the aerospace industry, precision and quality are paramount. PolyJet stands out in this sector for its ability to produce high-precision parts with excellent surface finish.

Aerospace companies use PolyJet for a variety of applications, including the production of lightweight, complex geometries and prototypes for wind tunnel testing. Furthermore, the technology’s multi-material capabilities enable the creation of detailed, color-coded assembly aids and instruction models, greatly aiding in the intricate assembly processes common in aerospace manufacturing.

Applications of PolyJet in the Medical Industry

The medical industry also greatly benefits from PolyJet’s unique capabilities. The technology’s high resolution and multi-material capabilities make it ideal for creating detailed anatomical models for surgical planning and patient education.

Moreover, PolyJet can be used to create customized medical devices, such as hearing aids and dental aligners, offering a level of personalization that is hard to achieve with other 3D printing technologies. Its ability to simulate a wide range of textures and colors also makes it possible to produce incredibly realistic training models for medical professionals.

While other 3D printing technologies find applications in these industries, PolyJet often stands out for its speed, precision, and versatility, making it a preferred choice for many professionals.

Conclusion

In conclusion, while each 3D printing technology has its strengths, PolyJet offers a unique combination of precision, versatility, and multi-material capabilities. As the technology continues to evolve, it is set to further revolutionize the 3D printing industry, offering exciting possibilities for innovation and design.