Are you curious about the materials commonly used in 3D printing? Well, look no further! In this article, we’ll dive into the world of 3D printing materials and explore their characteristics. From plastics like nylon, ABS, PLA, PETG, and TPU to metals such as stainless steel and titanium, we’ll cover it all. Not only that, but we’ll also discuss specialized materials like silicone and rubber-like resins for creating flexible objects. So, let’s get started on this exciting journey through the realm of 3D printing materials!

Plastics Used in 3D Printing

Plastics are commonly used in 3D printing because they offer a wide range of properties, such as strength, flexibility, and biodegradability. Advancements in plastic materials have led to exciting possibilities in the field of additive manufacturing. In the future, we can expect to see more applications of flexible 3D printing materials as they continue to improve and evolve.

When it comes to plastic materials used in 3D printing, there are several options available. Nylon (Polyamide) is known for its strength and flexibility, making it suitable for creating durable objects. ABS (Acrylonitrile Butadiene Styrene) is another popular choice due to its strength and availability in various colors. PLA (Polylactic Acid), on the other hand, is a biodegradable plastic derived from renewable resources that is easy to print with.

In terms of comparison, polyamide can simulate other polymer materials such as ABS or PET. While PLA can be compared to ABS plastic, it has lower durability and a lower melting point.

Overall, advancements in plastic materials have expanded the possibilities of 3D printing by offering greater strength, flexibility, and environmental sustainability. The future looks promising for the development of even more advanced plastics that will further enhance the capabilities of this technology.

Other Materials Used in 3D Printing

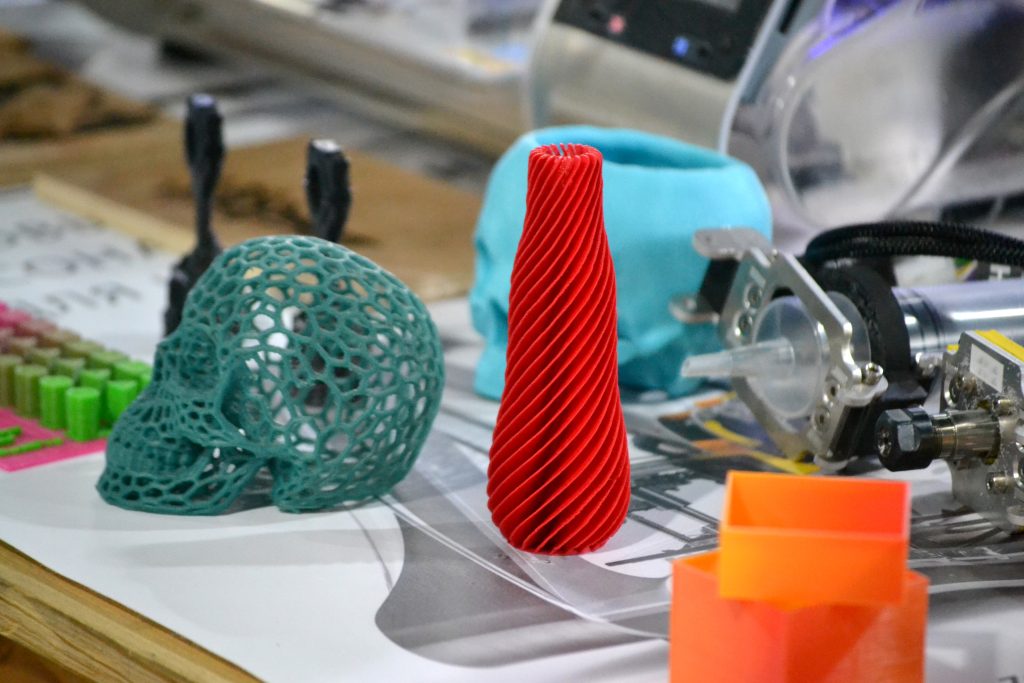

When exploring 3D printing, you’ll encounter a wide range of materials beyond plastics that can be used for creating objects, such as metals, resins, ceramics, and even food materials. These materials offer unique properties and open up new possibilities in the world of additive manufacturing.

Firstly, let’s talk about food materials. With the advancement of technology, it is now possible to 3D print using edible materials like chocolate, sugar, or pasta. This has revolutionized the culinary industry by allowing chefs to create intricate designs and customized shapes for their dishes.

Next are bio materials. These include cells and body tissues used for bioprinting applications such as organ or tissue regeneration. The ability to print with living cells opens up new frontiers in healthcare by allowing the creation of functional organs or replacements.

Lastly, we have conductive materials. Conductive carbomorph is a prime example that incorporates circuits and batteries into plastic parts. This reduces the need for assembly and enables additive manufacturing to replace traditional processes in electromechanical devices.

Flexible 3D Printing Materials

TPE and TPU are examples of flexible materials that can be used in 3D printing. These materials have gained popularity due to their unique properties and the wide range of applications they offer. Flexible 3D printing materials find extensive use in industries such as automotive, consumer goods, healthcare, and fashion.

One of the key advancements in flexible 3D printing technology is the development of improved material formulations. Manufacturers have been able to create materials with enhanced flexibility, elasticity, and strength. This has expanded the possibilities for creating complex geometries and functional prototypes.

When comparing different types of flexible 3D printing materials, TPE and TPU stand out for their excellent mechanical properties. TPE is known for its stretchability and rubber-like texture, making it suitable for applications requiring flexibility and impact resistance. On the other hand, TPU offers both flexibility and elasticity, making it an ideal choice for creating objects that need to return to their original shape after being deformed.

Other Characteristics of 3D Printing Materials

One important characteristic of 3D printing materials is their strength, which determines the durability and load-bearing capacity of printed objects. In addition to strength, there are other key characteristics that play a crucial role in the selection and application of materials for 3D printing.

Heat resistance is another important factor to consider when choosing 3D printing materials. Certain applications require materials that can withstand high temperatures without deformation or degradation. This is particularly relevant in industries such as aerospace and automotive where components may be exposed to extreme heat.

Conductivity is another characteristic that can be valuable in certain applications. Materials with electrical conductivity properties are used for creating circuit boards or sensors through additive manufacturing techniques.

Transparency is yet another desirable trait in some 3D printed objects. Transparent or translucent materials allow light to pass through, making them suitable for creating products like display cases or lighting fixtures.

Advanced and innovative materials are constantly being developed for 3D printing. These include carbon nanotubes and graphene embedded plastics, which offer strength and conductivity properties for applications like flexible touchscreens and solar panels. Additionally, specialized materials like Nitinol, an alloy of nickel and titanium, are utilized in medical implants due to their unique superelasticity and shape-changing properties.

Overall, considering the specific characteristics of 3D printing materials such as strength, heat resistance, conductivity, transparency, as well as exploring advanced and innovative options allows for expanded possibilities in additive manufacturing across various industries.

Ceramics and Composites

If you’re interested in ceramics and composites, you’ll find that they offer unique properties such as heat resistance and electrical insulation. Advancements in ceramic 3D printing have opened up new possibilities for creating complex shapes with high precision. Ceramic materials, like porcelain or zirconia, are used for various applications in different industries, including aerospace, automotive, and healthcare. For example, ceramic components are commonly used in gas turbines due to their ability to withstand high temperatures and harsh environments. In the medical field, ceramics are used for dental implants and bone substitutes because of their biocompatibility and strength.

Composite materials for 3D printing combine two or more substances to create materials with enhanced properties. Carbon fiber reinforced polymers (CFRPs) are a popular choice in industries such as bicycle manufacturing and aeronautics due to their high strength-to-weight ratio. These composites offer comparable strength to metal while being lighter.

The applications of ceramics and composites in different industries continue to expand as advancements in 3D printing technology improve. From creating intricate ceramic objects with precise details to producing strong composite parts with complex geometries, these materials play a vital role in pushing the boundaries of additive manufacturing.