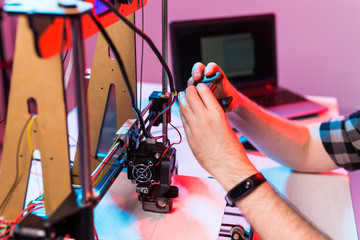

3D printing has revolutionized the way we manufacture objects, allowing us to transform digital designs into physical reality. However, printing complex shapes and overhangs can be challenging. That’s where support structures come into play.

These temporary structures provide stability and prevent deformities during the printing process.

In this discussion, we will explore the common types of support structures used in 3D printing and their applications.

Overview

Support structures play a vital role in ensuring successful 3D prints, especially when dealing with overhangs and complex designs. By understanding the common types of support structures available and implementing best practices, users can achieve high-quality prints with minimal post-processing efforts.

As 3D printing technology continues to advance, we can expect further improvements in support structure generation, making the process even more seamless and efficient.Overhangs in 3D Printing

One of the main challenges in 3D printing is dealing with overhangs. An overhang refers to a part of the design that extends beyond a 45-degree angle from the build plate.

Without proper support, these overhangs may sag, resulting in poor print quality or even failure. Support structures are essential to provide a solid foundation for these overhanging features and ensure successful prints.

Common Types of Support Structures

There are several types of support structures commonly used in 3D printing. Each type has its own advantages and limitations, depending on the complexity of the design and the material being used. Let’s take a closer look at some of these types:

1. Tree-like Supports

Tree-like supports, also known as branch-like supports, are widely used in 3D printing. As the name suggests, these structures resemble tree branches and offer excellent stability. They are easy to remove and minimize contact with the printed object, reducing the risk of damage.

Popular software such as PrusaSlicer and Ultimaker Cura can generate tree-like supports, making them easily accessible for users.

2. Grid Supports

Grid supports consist of a lattice-like structure that provides stability while minimizing material usage. These supports are relatively easy to remove and leave fewer marks on the printed object. However, they may require more material compared to other support types.

Slicing software such as Simplify3D and IdeaMaker offer grid support generation capabilities.

3. Solid Supports

Solid supports are dense structures that provide maximum stability but can be challenging to remove. These supports are suitable for complex prints with delicate or intricate features. They may leave more visible marks on the printed object compared to other support types.

Software like Meshmixer and Autodesk Fusion 360 offer options for generating solid supports.

4. Dissolvable Supports

Dissolvable supports are designed to be dissolved after the printing process, leaving no trace behind. They are typically used when printing with dual-extruder machines, where one extruder uses a soluble material that can be dissolved in water or a specific solvent.

Dissolvable supports offer excellent surface finish and are ideal for complex designs with hard-to-reach areas. Software such as PrusaSlicer and Ultimaker Cura support the generation of dissolvable supports.

Best Practices for Using Support Structures

To achieve the best results when using support structures, there are a few best practices to keep in mind:

Orientation and angle considerations

Properly orienting your model and adjusting the angle can help minimize the need for excessive support structures.

Support removal techniques

Different support structures require different removal techniques. Taking care during the removal process can prevent damage to the printed object.

Optimizing support settings in slicing software

Adjusting support density, spacing, and other settings in your slicing software can help optimize the balance between print quality and support material usage.