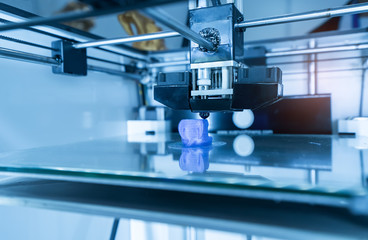

In the realm of technological innovation, 3D printing has undeniably made its mark. With its ability to transform digital designs into tangible objects, it has revolutionized various industries from healthcare to aerospace. Among the many facets of this technology, clear 3D printing clear stands out due to its unique applications and aesthetic appeal.

Overview: How to 3D Print Clear Plastic

Initially, see through 3D print was quite a challenge due to the inherent properties of materials used and limitations in technology. Early attempts often resulted in translucent rather than transparent objects. However, as technology advanced, so did the clarity of 3D printed objects.

Exploring Different Clear 3D Printing Techniques

The predominant techniques for clear 3D printing include Stereolithography (SLA), Digital Light Processing (DLP), and Selective Laser Sintering (SLS). SLA and DLP utilize photosensitive resins that are cured layer by layer, resulting in highly detailed and smooth surfaced objects. SLS, on the other hand, uses a high-power laser to fuse small particles of polymer powder, creating robust and versatile objects.

Innovations in Clear 3D Printing

The field of clear 3D printing is constantly evolving, with new innovations being introduced regularly. These advancements have led to improvements in the clarity, durability, and flexibility of printed objects.

Industries such as automotive, architecture, and medical have greatly benefited from these developments, using clear 3D printed components for prototyping, testing, and even end-use parts.

3D print clear plastic

Can you 3D print clear plastic? 3D print transparent plastic is a groundbreaking technique that has opened up new possibilities in various industries. Utilizing advanced technologies such as Stereolithography (SLA), Digital Light Processing (DLP), and Selective Laser Sintering (SLS), it allows the creation of transparent objects with a high level of detail and smooth surface finishes.

From architectural models to medical devices, clear plastic 3D prints serve a wide range of applications. They offer unique benefits such as visualizing internal structures and creating aesthetically pleasing prototypes. Despite certain challenges like maintaining the clarity during post-processing, ongoing technological advancements continue to enhance the effectiveness and accessibility of this innovative technique.

Accura 60

Accura 60 is a popular clear plastic material used in Stereolithography (SLA) 3D printing. Known for its excellent clarity and high tensile strength, it’s ideal for creating transparent prototypes or parts that mimic the qualities of glass or polycarbonate. From automotive to consumer goods industries, Accura 60 enables detailed visualization of internal features and creates aesthetically appealing models with a glass-like finish.

Case Studies

One such example of 3d print translucent application is in the medical field, where it is used to create patient-specific anatomical models for surgical planning. This not only improves the accuracy of surgeries but also enhances patient understanding and consent processes. However, despite its many benefits, clear 3D printing still faces challenges such as high costs and slow printing speeds.

The Future of Clear 3D Printing

Looking ahead, the future of 3d printing clear acrylic appears promising. With emerging trends like AI integration for improved design accuracy and the development of new, more efficient materials, the possibilities seem endless. As technology continues to advance, it’s anticipated that transparent 3D printing will become more accessible and prevalent in various industries.

In conclusion, clear 3D printing techniques have come a long way since their inception. With continuous innovations and advancements, they’re set to revolutionize how we conceptualize and create transparent objects. As we continue to explore this fascinating technology, the future of clear 3D printing shines bright with potential.