Did you know that objects can be brought to life through the process of 3D printing and scanning? In this discussion, we will explore the fascinating world of 3D scanning and reverse engineering.

You’ll discover how 3D scanners convert objects into mesh models and learn about the crucial step of converting these models into solid CAD drawings. We’ll also dive into the importance of scan accuracy, choosing the right scanner, integrating scanned objects into new designs, and ultimately 3D printing the final product.

The Process of 3D Scanning and Reverse Engineering

Reverse engineering is the process of converting a mesh model into a solid CAD drawing, allowing for the creation of replacement parts that match the original design. This process plays a crucial role in bridging the gap between 3D scanning and 3D printing. When it comes to scan and print or d print and scan workflows, reverse engineering provides a solution for creating accurate digital representations of physical objects.

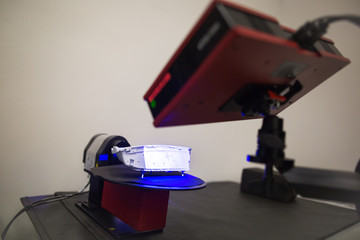

- To scan for 3D printing, you need to use a high-accuracy 3D scanner that can capture all the important details of the part. Tabletop structure light or laser scanners are commonly used for this purpose, with an accuracy level of ±100 or better.

- Depending on the complexity of the object, multiple scans may be required to capture deep recesses or different orientations.

- Once you have obtained the mesh model from scanning, you can refine it using software tools like Meshmixer. This allows you to repair small gaps and simplify the scan data, making it more manageable in CAD software. The goal is to import a refined mesh into CAD software equipped with reverse engineering tools.

Using CAD software

In CAD software, you can convert the scanned mesh into a solid model by extracting curves and surfaces from the scan data. This enables you to create new components that reference or incorporate elements from older designs. By subtracting the scanned model from another solid body, you can ensure precise fitment.

With the solid CAD drawing in hand, you are ready for 3D printing. Formlabs’ Rigid 4000 Resin is an excellent choice as it offers strength and precision comparable to engineering-grade scanners.

By following these steps of scanning and reverse engineering, you can bring objects to life through 3D printing while maintaining their original design integrity.

Enhancing Scan Accuracy With Temporary Matte Powder

To improve scan accuracy, apply a temporary matte powder to glossy surfaces. When scanning objects for 3D printing, glossy surfaces can degrade the quality of the scan. To overcome this issue, you can use a temporary matte powder to enhance the accuracy of the scan. This is particularly important for reflective and transparent surfaces that cannot be scanned without a matte coating.

When using a 3D scanner to capture an object for 3D printing, it is essential to choose a high-accuracy scanner with an accuracy of ±100 or better. Tabletop structure light or laser scanners are suitable for this purpose. However, for objects with deep recesses or complex shapes, multiple scans from different angles may be necessary.

After scanning the object, some scanners produce large mesh files that can slow down subsequent steps in the process. To address this, scanner software can repair small gaps and simplify the scan data to make it more manageable in CAD software.

Incorporating a refined mesh into CAD software equipped with reverse engineering tools allows you to convert the scan into a solid model. From there, you can design new components based on dimensions extracted from the scan and create accurate jigs or replacement parts.

Choosing the Right 3D Scanner for Accurate Results

When choosing the right 3D scanner, you want to consider your specific needs and find one that complements high accuracy 3D printing. Here are some factors to consider:

Scanner Accuracy

Look for a scanner with a high level of accuracy, such as ±100 or better, to ensure precise 3D scanning results.

Scanning Technology

Consider the type of scanning technology used by the scanner, such as tabletop structure light or laser scanners, which are suitable for capturing important sections of the part.

Software Capabilities

Check if the scanner software offers features like repairing small gaps and simplifying scans to make the data more manageable in CAD. Tools like Meshmixer can also be useful for refining scanned meshes.

File Size and Compatibility

Some scanners produce large mesh files that can slow down subsequent steps. Make sure the scanner’s file format is compatible with your CAD software and that it produces manageable file sizes.

Support and Resources

Look for a company that provides ongoing support, updates, tutorials, and resources to help you maximize your scanning experience.

Integrating Scanned Objects Into New Designs

Integrating scanned objects into new designs can enhance the functionality and accuracy of the final product. By incorporating existing objects into your design process, you can leverage their complex surfaces and dimensions to create more efficient and precise designs.

- When integrating scanned objects, it is important to start by refining the scan itself. Applying a temporary matte powder improves scan accuracy by minimizing the impact of glossy or reflective surfaces.

- Using a high-accuracy 3D scanner, capture the important sections of the object, reorienting and rescanning as necessary for deep recesses.

- Once you have a refined mesh from scanning, import it into CAD software equipped with reverse engineering tools. Convert the scan into a solid model and use semi-automatic surfacing techniques to extract curves for accurate reference.

- By subtracting the scan from another solid body, you can ensure a precise fit when creating new components that reference or incorporate older designs.

- Finally, utilize 3D printing technology to bring your new design to life. High-accuracy 3D printers like Formlabs’ stereolithography (SLA) printers offer precision comparable to engineering-grade scanners. Printing with materials like Rigid 4000 Resin provides strength and accuracy for creating functional jigs and components.

Overall, integrating scanned objects into your design process allows for more accurate replication, restoration, reverse engineering, and metrology applications. With careful scanning, refining, integration, and printing processes in place, you can achieve high levels of accuracy in your final product while ensuring quality assurance throughout your project.

3D Printing the New Design With High Accuracy

The high-accuracy 3D printer ensures precise replication of the new design. With this advanced technology, you can bring your ideas to life with accuracy and efficiency. Here are five key advantages of using a high-accuracy 3D printer for printing your new design:

High precision

The high-accuracy 3D printer guarantees accurate reproduction of intricate details and complex geometries, ensuring that your design is faithfully replicated.

Time-saving

The fast printing speed of the high-accuracy 3D printer allows for quick production of multiple copies, reducing lead times and increasing productivity.

Cost-effective

By eliminating the need for traditional manufacturing methods such as molding or casting, the high-accuracy 3D printer significantly reduces production costs, making it an economical choice.

Versatility

The high-accuracy 3D printer can work with a wide range of materials, including plastics, metals, and even composites, giving you flexibility in material selection for your new design.

Customization

With the high-accuracy 3D printer, you have the freedom to customize every aspect of your design. Whether it’s adjusting dimensions or adding personalized features, you have full control over the final product.

Benefits and Quality Assurance of 3D Scanning and Printing

Discover the benefits and ensure quality assurance with 3D scanning and printing technology. By utilizing these advanced technologies, you can unlock a multitude of advantages for your projects.

- First and foremost, 3D scanning allows for accurate replication and restoration of objects. Whether you need to recreate complex parts or restore historical artifacts, 3D scanning provides the precision required for successful outcomes.

- Additionally, 3D printing complements the scanning process by bringing your designs to life. With high accuracy and strength, Formlabs’ Rigid 4000 Resin ensures that your printed components are durable and reliable. This level of precision is crucial in reverse engineering projects where quality assurance is paramount.

- To further enhance your workflow, it’s important to choose the appropriate 3D scanner based on your specific needs. By selecting scanners that complement high accuracy 3D printing, you can achieve optimal results.

- Furthermore, exploring the various applications of 3D scanning and printing technology can open up new possibilities in industries such as replication, restoration, reverse engineering, and metrology.

- Accurate measurements and inspections are essential in metrology applications, while efficient replication options benefit industries such as architecture and design.

Matter and Form: Leaders in Flexible 3D Scanning Technology

Matter and Form offers a range of portable and easy-to-use 3D scanners for various industries. Their technology is known for its accuracy and ease of use, making it a popular choice among professionals.

Here are five reasons why Matter and Form’s 3D scanning technology stands out:

Portability

Matter and Form’s scanners are designed to be portable, allowing you to easily bring them to different locations or work on the go.

Ease of Use

The scanners are user-friendly and intuitive, making them accessible even for those without extensive technical knowledge.

High Resolution

Matter and Form’s scanners are capable of capturing high-resolution 3D models, ensuring that every detail is accurately captured.

Compatibility

The hardware is compatible with various operating systems, allowing for seamless integration with existing software.

Ongoing Support

Matter and Form provides ongoing support and updates for their hardware products, ensuring that customers have access to the latest advancements in technology.

With these features, Matter and Form’s 3D scanning technology offers a reliable solution for professionals in industries such as architecture, design, prototyping, product development, medical field, gaming, animation, virtual reality.

Applications of 3D Scanning and Printing in Various Industries

The applications of 3D scanning and printing are vast and diverse, with the potential to transform various industries. In architecture and design, these technologies allow for the creation of detailed prototypes that can be used to visualize and test concepts before production.

In the medical field, custom prosthetics can be created using precise scans of patients’ bodies, improving comfort and functionality. For gaming and animation industries, 3D scanning enables the creation of realistic digital assets for immersive experiences. Virtual reality is also benefiting from these technologies as they enable the development of lifelike environments.

The accuracy and quality offered by 3D scanning and printing make them invaluable tools in replicating objects with intricate details. Whether it’s recreating historical artifacts or manufacturing spare parts for machinery, these technologies ensure precision in replication.

Additionally, reverse engineering techniques can be employed to create new designs based on existing objects or incorporate older designs into new products.