Imagine a world where complex structures and intricate designs can be brought to life with just a few clicks. Thanks to advancements in technology, 3D printing has emerged as a game-changer in various industries. But what if we take it a step further and combine the power of 3D printing with the strength and versatility of carbon fiber?

In this discussion, we will explore the impact of carbon fiber on 3D printing technology and how it is revolutionizing industries with its exceptional strength and precision.

Carbon Fiber: An Overview

Carbon 3D fiber is a lightweight, high-strength material made from thin strands of carbon atoms. These strands are tightly woven together to form a strong and durable structure. Carbon fiber is known for its impressive properties, including high stiffness, low weight, corrosion resistance, and excellent thermal conductivity. It has found applications in various industries such as aerospace, automotive, sports equipment, and more.

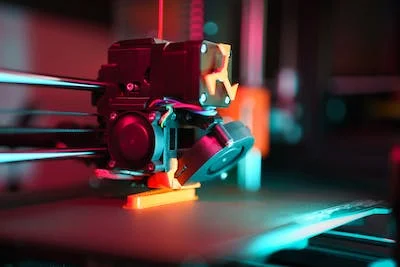

Carbon Fiber 3D Printing: A Game Changer

Carbon fiber 3D printing, also known as carbon fiber-reinforced polymer (CFRP) 3D printing, combines the benefits of both carbon fiber and 3D printing technologies. By incorporating carbon fiber into the printing process, manufacturers can create parts and components that are not only lightweight but also incredibly robust. This technology opens up new possibilities for creating complex structures with unparalleled strength and precision.

Benefits and Advantages of Carbon Fiber 3D Printing

The use of carbon fiber in 3D printing brings several advantages to different industries. First and foremost, the lightweight nature of carbon fiber allows for the production of lighter components, resulting in improved fuel efficiency in the automotive and aerospace sectors. Furthermore, carbon fiber’s exceptional strength-to-weight ratio makes it ideal for applications where both strength and weight reduction are crucial.

Carbon fiber 3D printing also enables the creation of intricate designs and complex geometries that would be challenging or impossible to achieve using traditional manufacturing methods. This capability is particularly useful in industries such as architecture, where customized designs and structures are in high demand.

Examples of Successful Applications and Case Studies

Application in the automotive industry

The automotive industry has been quick to adopt carbon fiber 3D printing technology. A carbon company like Bugatti have utilized this technology to produce lightweight and aerodynamic components for their high-performance sports cars. The use of carbon fiber 3D printing has resulted in improved performance and reduced overall vehicle weight.

Application in the aerospace industry

In the aerospace industry, where weight reduction plays a critical role in fuel efficiency and cost savings, carbon fiber 3D printing has opened up new possibilities. NASA has been exploring the use of this technology for creating lightweight, strong, and heat-resistant parts for space exploration missions.

Application in the medical industry

The medical industry is another sector benefiting from the advancements in carbon fiber 3D printing. Customized prosthetics, orthopedic implants, and surgical instruments can now be produced with greater precision and strength, enhancing patient outcomes and improving quality of life.

Challenges and Future Developments

While carbon fiber printing offers immense potential, there are still some challenges that need to be addressed. One of the main hurdles is the cost of carbon fiber materials and the complexity of the printing process, which often requires specialized equipment. However, ongoing research and development efforts are focused on reducing costs, improving efficiency, and expanding the range of printable materials.

Looking ahead, the future of carbon fiber 3D printing looks promising. Researchers are exploring new materials and techniques to further enhance the strength, durability, and versatility of printed carbon fiber components. As the technology continues to evolve, we can expect to see even more innovative applications and widespread adoption across various industries.

Carbon fiber 3D printing has the potential to revolutionize industries with its exceptional strength and precision. By combining the advantages of carbon fiber, carbon fiber 3D printer and 3D printing technologies, manufacturers can create lightweight, strong, and complex structures that were once unimaginable. From automotive and aerospace to medical applications, carbon fiber 3D printing is reshaping the way we design and manufacture products. As research and development efforts continue, we can look forward to a future where carbon fiber 3D printing becomes a mainstream manufacturing technique, unlocking endless possibilities for innovation and advancement.