Are you interested in learning the basics of 3D printing?

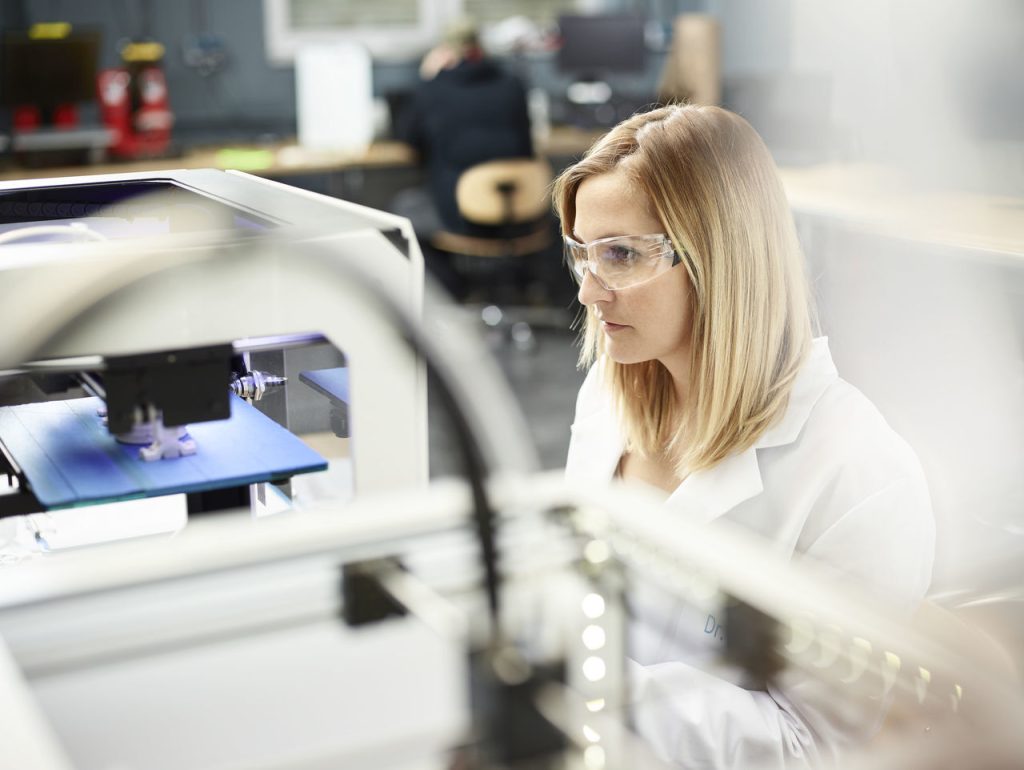

In this article, we’ll walk you through the process of creating physical objects from digital models using layers of material.

You’ll discover the various techniques and materials used in 3D printing, as well as its applications in industries like healthcare, fashion, and transportation.

With 3D printing, you’ll enjoy design freedom, reduced material waste, and faster production cycles.

Get ready to delve into the exciting world of 3D printing and unlock new possibilities.

The History of 3D Printing

You may be interested to know that 3D printing technology has been around since the 1980s. It was initially used for rapid prototyping in industries like automotive and aerospace. The inventors and pioneers of 3D printing, Chuck Hull and Scott Crump, made significant advancements in the technology, leading to its widespread adoption.

Over the years, 3D printing technology has evolved and become more accessible, revolutionizing the manufacturing industry. It has allowed for faster production cycles, reduced costs, and increased design flexibility. The impact of 3D printing on the manufacturing industry cannot be overstated, as it has enabled the creation of complex geometries and intricate details that were previously impossible to achieve.

This has opened up new possibilities for innovation and product development across various sectors.

Understanding the Technology Behind 3D Printing

The technology behind 3D printing involves the layer-by-layer addition of materials to create physical objects. Advancements in 3D printing technology have opened up exciting possibilities for the future. With continuous improvements, 3D printing is poised to revolutionize the manufacturing industry.

The impact of 3D printing on manufacturing is significant, as it allows for faster production cycles, reduced waste, and greater design freedom. Manufacturers can create complex geometries and intricate details that were previously challenging or impossible. Moreover, 3D printing enables customization and on-demand production, leading to more efficient supply chains.

As technology continues to evolve, the future prospects of 3D printing are promising. It has the potential to transform various industries, from healthcare to automotive, by providing innovative solutions and driving economic growth.

Materials and Filaments Used in 3D Printing

Different types of materials and filaments are used in 3D printing to create physical objects layer by layer. The properties and characteristics of these materials play a crucial role in determining the quality and functionality of printed objects.

Some common types of filaments used in 3D printing include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and TPU (Thermoplastic Polyurethane). Each filament has its own unique set of properties, such as strength, flexibility, heat resistance, and printability.

When choosing the right filament for your 3D printing project, it is important to consider factors like the desired object’s purpose, required durability, and environmental conditions it will be subjected to. By carefully analyzing these considerations, you can ensure that your 3D-printed objects meet your specific needs and requirements.

3D Printing Process

To start the 3D printing process, first, select a 3D model and import it into slicing software. This software will convert the model into a format that the 3D printer can understand.

Before printing, it’s important to troubleshoot common issues that may arise. Check the printer’s settings and make sure the bed is leveled properly. Clogged nozzles and filament jams are common problems, so regularly clean and maintain your printer.

To achieve high-quality prints, ensure that the printer is calibrated correctly and use the appropriate settings for the desired level of detail. Experiment with different materials and settings to find what works best for your prints.

Regular maintenance and care for your 3D printer will prolong its lifespan and ensure consistent performance. Clean the printer regularly, lubricate moving parts, and replace worn-out components as needed.

Exploring the Applications of 3D Printing

3D printing offers a wide range of applications in various industries and sectors. In healthcare, the advantages of 3D printing are significant. It allows for the creation of customized medical implants, prosthetics, and even organs. This technology has the potential to revolutionize patient care and improve treatment outcomes.

The fashion industry has also been impacted by 3D printing. Designers can now create intricate and unique pieces with ease, pushing the boundaries of traditional fashion manufacturing. From clothing to accessories, 3D printing has opened up new possibilities for creativity and innovation.

In education, emerging applications of 3D printing are transforming the way students learn. It allows for hands-on experiences and the creation of physical models, enhancing understanding and engagement.

As 3D printing continues to evolve, its applications will only continue to expand, bringing about exciting advancements in various fields.