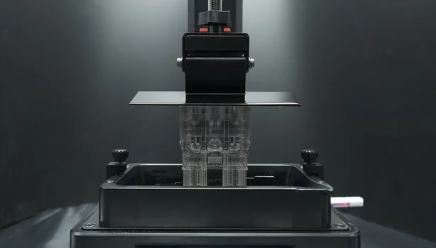

Metal 3D printing is revolutionizing the way we produce metal parts and products. With the global metal additive manufacturing market projected to reach $18.5 billion by 2032, it’s clear that metal 3D printing is here to stay. Discover how this groundbreaking technology is shaping the industry and explore the exciting possibilities it holds for the future. Get ready to witness the transformative power of metal 3D printing.

Market Size and Growth of 3D Printing Metals

The market for 3D printing metals is experiencing significant growth and expansion, driven by the increasing demand for metal powders in the 3D printing process. Metal additive manufacturing trends and advancements in the industry have contributed to this growth. One notable advancement is the use of hybrid composites, which can reduce the weight of products while maintaining strength. Additionally, the impact of LinkedIn on the metal 3D printing market cannot be overlooked.

The platform provides a valuable networking opportunity for professionals in the industry, facilitating collaboration and knowledge sharing. Another factor driving the market is the development of cost-effective printers. Traditionally, metal 3D printers have been expensive, limiting their accessibility to larger companies. However, companies like Xact Metal and One Click Metal have focused on making metal 3D printers more affordable, opening up opportunities for hobbyists, startups, and small businesses. As the market continues to grow, we can expect to see further advancements in metal additive manufacturing, expanding materials portfolios, and the localization of manufacturing processes.

Recent Developments in the 3D Printing Metals Market

Explore the latest advancements in the 3D printing metals market with these recent developments:

– Renishaw plc collaborated with Sandvik Additive Manufacturing to qualify new additive manufacturing materials. This partnership aims to enhance the capabilities of metal 3D printing by exploring innovative materials that can be used in the manufacturing process.

– GE Additive entered into a five-year cooperative research and development agreement with the US Department of Energy’s Oak Ridge National Laboratory. This partnership focuses on advancing the understanding and application of metal 3D printing in industries such as aerospace and energy.

– 3D Systems Corporation was awarded a contract worth USD 15 million from the Combat Capabilities Development Command Army Research Laboratory. This contract highlights the growing importance of metal 3D printing in defense applications and showcases the potential for further development and adoption in this sector.

These recent developments demonstrate the continuous growth and expansion of the metal 3D printing industry. From collaborations to contracts, companies are actively investing in research and development to enhance the capabilities and applications of metal 3D printing. As a result, the market is poised for significant growth in the coming years.

Key Players in the 3D Printing Metals Market

Now let’s delve into the key players in the 3D printing metals market and their significant contributions to the industry. The market analysis of the 3D printing metals market indicates strong growth drivers, such as the increasing demand for metal powders in the 3D printing process. Several key players have emerged in this market, including 3D Systems Corporation, Stratasys Ltd., Renishaw plc, General Electric Company, Carpenter Technology Corporation, Materialise NV, Voxeljet AG, Sandvik AB, EOS GmbH Electro Optical Systems, The ExOne Company, and Proto Labs, Inc.

3D Systems Corporation is a leading player in the market, offering a wide range of metal powders and 3D metal printers. The company also provides software solutions for 3D printing and serves industries such as aerospace & defense and medical & dental.

Stratasys Ltd. is another key player, focusing on expanding its Stratasys Direct Manufacturing business. The company develops, manufactures, and markets materials for the metal 3D printing marketplace and has a strong application base across various industries.

These key players have contributed significantly to the industry through their technological advancements and industry trends. They have played a crucial role in driving the growth of the 3D printing metals market and will continue to shape its future.

Hybrid Composites and Their Impact on Manufacturing

As we continue our discussion on the key players in the 3D printing metals market, let’s now delve into the impact of hybrid composites on manufacturing, which is gaining momentum in the industry. Hybrid composites, which combine the strengths of different materials, have the potential to revolutionize various sectors. Here are some key points to consider:

– Hybrid composites and sustainability: By using a combination of materials, hybrid composites can reduce the weight of products and increase their strength, leading to more efficient and sustainable manufacturing processes.

– Integration of hybrid composites in the automotive industry: Hybrid composites are being integrated into the production of automobiles, resulting in lighter and more fuel-efficient vehicles. This technology is also contributing to the development of electric and hybrid vehicles.

– Advancements in hybrid composite manufacturing: Significant advancements have been made in the manufacturing processes of hybrid composites, enabling the production of complex and customized parts. This has opened up new possibilities for design and functionality in various industries.

– Hybrid composites in aerospace applications: The aerospace industry is increasingly utilizing hybrid composites in the production of aircraft components. These materials offer high strength-to-weight ratios, improved fuel efficiency, and reduced emissions.

– Benefits of hybrid composites in the renewable energy sector: Hybrid composites are playing a crucial role in the renewable energy sector, particularly in the production of wind turbine blades. These materials offer increased durability and improved performance, leading to more efficient and reliable renewable energy generation.

The Role of LinkedIn in the 3D Printing Industry

LinkedIn plays an essential role in connecting professionals and driving collaboration in the 3D printing industry. As a platform for industry networking, LinkedIn allows professionals to establish connections with others in the field, fostering relationships and facilitating knowledge sharing. Through LinkedIn, individuals can stay updated on the latest industry trends and developments, shaping their professional development and allowing them to stay ahead of the curve. Additionally, LinkedIn serves as a valuable tool for job recruitment, connecting companies with skilled professionals in the 3D printing industry.

Recruiters can utilize the platform to find candidates with the specific expertise and experience required for their organizations. Furthermore, LinkedIn’s influence on industry trends cannot be overlooked. Professionals can share their insights and expertise, sparking discussions and driving innovation in the 3D printing industry. By leveraging LinkedIn’s vast network and resources, professionals can contribute to the growth and advancement of the industry as a whole. In summary, LinkedIn plays a crucial role in industry networking, professional development, job recruitment, influencing industry trends, and facilitating knowledge sharing in the 3D printing industry.

Other Related Topics in the 3D Printing Industry

To delve further into the 3D printing industry, let’s explore other related topics that play a significant role in shaping its future. Here are some key points to consider:

– 3D printing materials: The availability and development of high-performance powders and specialized materials are crucial for the advancement of metal 3D printing. Research and innovation in this area aim to expand the range of printable materials, reduce costs, and improve print quality.

– Metal 3D printing applications: Metal additive manufacturing has found significant applications in industries such as aerospace and healthcare. The ability to produce complex, customized parts with high precision and reliability makes metal 3D printing a preferred choice for critical components in these sectors.

– Metal 3D printing challenges: Despite its potential, metal 3D printing still faces challenges such as high entry costs for larger companies and limited availability of affordable printers. However, advancements in technology and the emergence of lower-cost printers are addressing these challenges and driving wider adoption.

Metal 3D printing is poised to revolutionize manufacturing processes in various industries. As advancements continue to be made in 3D printing materials, applications, and addressing challenges, the future looks promising for metal additive manufacturing.

Predictions for the Future of Metal 3D Printing

You will frequently see rapid advancements in metal 3D printing as it continues to shape the future of manufacturing. The predictions for the future of metal 3D printing are exciting and offer numerous opportunities for innovation and growth. One prediction is the rapid adoption of metal additive manufacturing (MAM) solutions in various industries such as automotive, semiconductor capital equipment, and machine components for rocketry.

This widespread adoption will lead to increased efficiency and productivity in manufacturing processes. Another prediction is the emergence of more mass customization options, particularly in the medical industry for patient-specific medical devices. This will revolutionize the healthcare sector, allowing for highly personalized treatments and improved patient outcomes. Additionally, metal AM is expected to play a critical role in transforming manufacturing workflows and supply chains, addressing delays in logistics and reducing inventory. Material innovation will also be a key focus, with an increase in available materials pushing MAM from prototyping to mass production. Finally, there will be a strong emphasis on post-processing advancements, aiming to improve the overall cost and achieve excellent surface finishes. These predictions highlight the immense potential of metal 3D printing in revolutionizing manufacturing processes and opening up new possibilities for customization, efficiency, and innovation.

Shaping the Future of Metal Additive Manufacturing Today

Shape the future of metal additive manufacturing today by embracing the advancements and opportunities it offers. The industrialization of technology has paved the way for lights-out operations, enabling printers to operate for long hours without interruption. This allows for increased productivity and efficiency in the manufacturing process. To fully leverage the potential of metal additive manufacturing, it is crucial to collect historical data to ensure the success and quality of lights-out operations. By analyzing this data, manufacturers can identify areas for improvement and optimize the utilization of resources.

To shape the future of metal additive manufacturing, collaboration is key. Companies like APG can provide valuable assistance in industrializing the technology and generating real-world feedback on applications. Collaboration between equipment OEMs, parts producers, and customers is essential to align on industrializing the evolving technology. This collaborative approach promotes continuous adaptation and incorporation of innovative equipment into the process flow, further enhancing efficiency and productivity.

By embracing metal additive manufacturing, manufacturers can realize the total cost benefits it offers. This technology enables the production of complex geometries and reduces material waste, resulting in cost savings. Additionally, the utilization of resources is optimized, as the process requires only the necessary amount of material. These benefits make metal additive manufacturing a compelling choice for industries such as automotive, aerospace, and healthcare.

Metal Additive Manufacturing – the Future of Metal Manufacturing

Embrace the future of metal manufacturing today by exploring the potential of metal additive manufacturing in revolutionizing your production processes. Metal additive manufacturing, also known as 3D printing, holds numerous advantages for the manufacturing industry. One of the key benefits is the total cost benefits it offers. By utilizing metal additive manufacturing, you can reduce costs associated with traditional metal manufacturing methods, such as tooling and material waste. Additionally, historical data utilization is crucial in showcasing the superiority of metal additive manufacturing over traditional methods. By analyzing past data, you can identify areas for improvement and optimize your production processes.

To fully unlock the potential of metal additive manufacturing, it is important to explore additional resources. There are numerous materials, technologies, and techniques available that can enhance your metal manufacturing capabilities. By staying informed and continuously learning about the latest advancements in metal additive manufacturing, you can stay ahead of the competition and maximize the benefits for your business.

Another advantage of metal additive manufacturing is its remote capabilities. The COVID-19 pandemic highlighted the importance of remote manufacturing, and metal 3D printing emerged as a preferred choice for companies facing shipping hindrances. With metal additive manufacturing, you can produce parts and products locally, reducing reliance on global supply chains and ensuring a more resilient manufacturing process.

Lastly, the expanding materials portfolio in metal additive manufacturing is a significant development. Limited availability and high costs of metal powders have been a hindrance, but with ongoing research and development, new chemistries and high-performance metals are being explored. This expansion in materials allows for greater design flexibility and opens up new possibilities for metal manufacturing.

Newsletter Signup for Metal Additive Manufacturing Updates

Stay informed and stay ahead of the competition by signing up for our newsletter to receive regular updates and industry news on metal additive manufacturing. Our newsletter is a valuable resource that will keep you up to date with the latest advancements in metal 3D printing, including cost-effective printers, an expanded materials portfolio, and the benefits of localized manufacturing. Here’s why you should subscribe to our metal additive manufacturing newsletter:

– Metal 3D Printing Advancements: Our newsletter will provide you with insights into the latest advancements in metal 3D printing technology. From new printing techniques to improvements in post-processing and surface structure, you’ll stay informed on the cutting-edge developments that are shaping the future of metal manufacturing.

– Cost-Effective Printers: We will keep you updated on the latest developments in affordable metal 3D printers. You’ll learn about companies that are making metal 3D printing more accessible by offering printers with price tags below $100,000. Discover how these lower-cost printers are revolutionizing the industry and enabling smaller companies to enter the metal additive manufacturing market.

– Expanded Materials Portfolio: Our newsletter will highlight the expanding range of printable materials in metal additive manufacturing. You’ll learn about startups exploring new chemistries and high-performance metals, such as aluminum, to broaden the materials available for 3D printing. Stay informed on the latest developments in specialized powders that improve print quality and reduce costs.

Additive Manufacturing and Its Applications

How can additive manufacturing revolutionize your manufacturing process? Additive manufacturing, also known as 3D printing, offers a wide range of applications that can significantly enhance your production capabilities. One of the key advantages is its cost effectiveness. Traditional manufacturing methods often involve high tooling costs and wastage of materials, but additive manufacturing allows for the precise deposition of materials, minimizing material waste and reducing overall costs.

Another important aspect is localized production. With additive manufacturing, you have the ability to produce components on-site, eliminating the need for complex supply chains and reducing lead times. This localized production also enables customization and personalization, as you can easily modify designs and produce unique products tailored to specific customer requirements.

Furthermore, additive manufacturing advancements have led to an expansion of available materials. From metals to polymers and even composites, a wide variety of materials can now be used in the 3D printing process. This materials expansion opens up new possibilities for creating complex geometries and functional parts that were previously difficult or impossible to manufacture using traditional methods.

Market Growth and Factors Driving Metal 3D Printing

Expanding the market for metal 3D printing is driven by the increasing demand for innovative manufacturing solutions. Several factors are contributing to the growth of the metal 3D printing market:

– Lower cost printers: Established technologies like laser powder bed fusion and electron beam melting can be costly, with prices reaching up to $1 million. However, companies like Xact Metal and One Click Metal have focused on making metal 3D printers more affordable, with price tags below $100,000. This has allowed hobbyists, startups, and larger companies to enter the manufacturing industry.

– Expanding materials: The limited availability of high-performance powders and the high costs of metal powders have hindered the penetration of metal additive manufacturing. However, material startups are exploring new chemistries and high-performance metals like aluminum to expand the range of printable materials. Specialized companies are also manufacturing proprietary powders to improve print quality and reduce costs.

– Localized manufacturing: Metal 3D printing offers the ability to manufacture products locally, reducing reliance on global supply chains. This not only provides a more sustainable manufacturing method but also enables the production of a wide range of products beyond solid metal parts. Metal 3D printing can be used for printing solar cells, LEDs, capacitors, circuit boards, and microprocessors.

These factors, along with the remote capabilities and historical data provided by metal 3D printing, are driving the market growth and positioning metal 3D printing as the future of manufacturing.