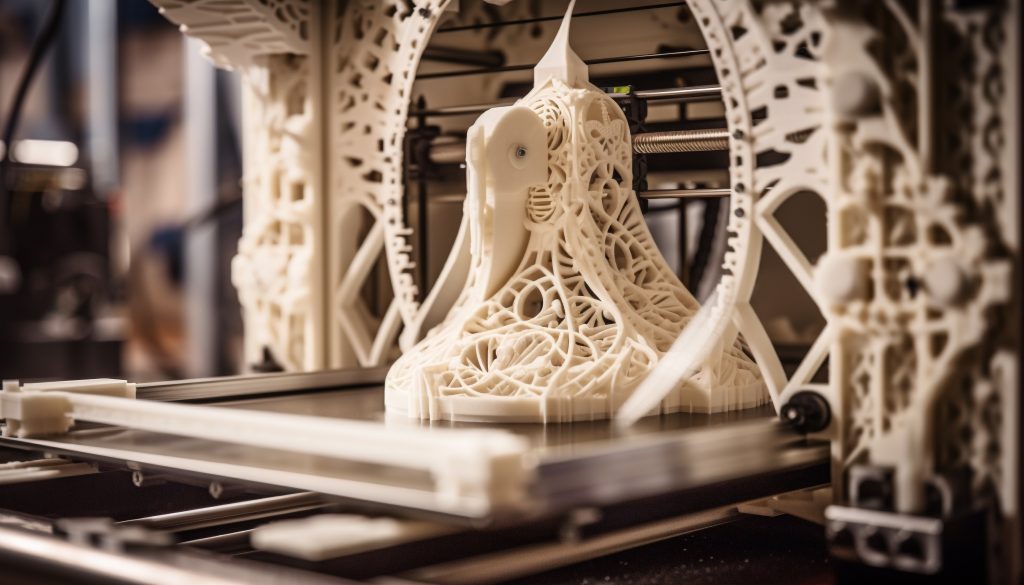

Are you ready to take your 3D printing skills to the next level? Look no further! This article provides you with pro tips and techniques to enhance your 3D printing experience. From setting up and maintaining your printer to troubleshooting common issues, we’ve got you covered. Discover the importance of calibration, choosing the right printer, and using high-quality filament and print bed adhesives for successful prints. Streamline your workflow and access additional resources to achieve consistent and high-quality results. Let’s dive in and elevate your 3D printing projects!

Printer Setup and Maintenance

Start by ensuring that you have properly set up and maintained your 3D printer. Proper maintenance is essential for achieving reliable and accurate results. Regularly check the printer’s components such as belts, gears, wheels, and the z-axis screw to ensure they are in good condition. Additionally, calibrate your printer for optimal performance. This includes leveling the build plate to ensure uniform prints. You can manually level the build plate using knobs or use auto bed leveling with a sensor for more accurate results. Remember, even with auto bed leveling, manual leveling is still necessary. Another important aspect of printer setup is choosing the right printer. Consider factors beyond just size, as small format machines can produce detailed models. Look for advanced features like an all-metal hot end and bed leveling capabilities. Lastly, be prepared to troubleshoot common issues that may arise during the printing process. Stay informed by following online tutorials and guides for proper troubleshooting techniques. By properly setting up and maintaining your 3D printer, you can ensure better print quality and a smoother printing experience.

Filament and Print Bed Adhesive

Ensure successful 3D prints by using high-quality filament and proper print bed adhesive. Moisture control is essential when it comes to filament. To prevent issues, store filament in a dry box or use a filament dryer. Weighing the filament before each print helps avoid wastage. High-quality filaments reduce warping and improve print quality. Print bed preparation is another crucial step. Using print bed adhesives such as Magigoo and DimaFix creates a solid bond between the object and the build plate. This reduces waste from failed prints and improves the quality of prints regardless of the material used. If you encounter print adhesion issues, consider adhesive alternatives like glue sticks, hairspray, or painter’s tape. Choosing the right filament is also important. Different filaments have varying properties, such as strength, flexibility, and heat resistance. Understanding your project requirements and selecting the appropriate filament will greatly impact the success of your 3D prints. By controlling moisture, preparing the print bed properly, exploring adhesive alternatives, and selecting the right filament, you can achieve high-quality, successful 3D prints.

Calibration and Temperature Control

To achieve optimal print quality, it is important to focus on calibration and temperature control in your 3D printing projects. Calibration techniques such as extruder calibration and nozzle height adjustment are crucial for accurate and consistent prints. Start by calibrating the extruder steps to ensure the proper amount of filament is extruded. This can be done by measuring the actual filament length that is extruded and adjusting the steps accordingly. Additionally, adjusting the nozzle height is essential for proper filament deposition and preventing collisions with the print bed. Proper calibration of the nozzle height ensures a uniform first layer and improves overall print quality.

Temperature control methods are also important for achieving successful prints. PID temperature calibration helps in accurately regulating the temperature of the nozzle. This calibration process determines the optimal PID values for your specific printer and helps in maintaining a stable temperature throughout the printing process. Accurate temperature regulation improves flow rate consistency, resulting in better material bonding between layers and higher-resolution prints.

Troubleshooting and Print Removal

Regularly clean the nozzle to maintain optimal print quality and prevent clogs or jams. Here are some nozzle maintenance tips to help you troubleshoot and remove prints effectively:

- Use cleaning techniques: Clean the nozzle regularly using a soft metal brush to remove any hardened plastic. This will ensure smooth filament flow and prevent clogs.

- Employ troubleshooting methods: If you encounter print difficulties, try using compressed air to blow away any residue or debris from the nozzle. Be careful not to damage the nozzle with side cutters.

- Discover print removal hacks: Freezing PLA prints can make removal easier. Lower the print bed temperature or cool it with a fan, or even place it in the freezer. The cold temperature causes shrinkage, allowing for easy removal of the print.

- Overcome difficulties with PLA prints: PLA prints can sometimes be challenging to remove. Utilize the power of freezing by placing the print in the freezer for a few minutes. This will make the print shrink and release its grip on the print bed, making removal easier.

Workflow Optimization and Additional Resources

Optimize your workflow for efficient and successful 3D printing projects. Workflow optimization is crucial to ensure that your 3D printing process is streamlined and productive. By implementing effective strategies and utilizing the right tools, you can maximize your output and achieve high-quality prints.

One important aspect of workflow optimization is staying organized. Keep your workspace clean and tidy, and create a system for storing and organizing your filaments, tools, and accessories. This will help you locate items quickly and minimize the time spent searching for them.

In addition to organization, utilizing advanced software features can greatly enhance your workflow. Take advantage of features like Ultimaker Cura and Prusa Slicer to optimize your print settings and increase efficiency. These software programs offer advanced options for customization and fine-tuning, allowing you to achieve the best results possible.

When encountering challenges during the printing process, it is important to have troubleshooting techniques at your disposal. Research and learn from others’ experiences, and explore unconventional methods to solve issues. Online communities and forums can be valuable resources for troubleshooting tips and solutions.

To further optimize your workflow, consider investing in additional tools and accessories that can enhance your printing experience. These may include filament dryers, filament sensors, or upgraded components for your printer. These tools can improve the reliability and consistency of your prints.

Benefits of 3D Printing

You will frequently experience various benefits when utilizing 3D printing technology. Here are some key advantages:

- Rapid prototyping: 3D printing allows for quick and iterative design iterations, reducing the time and cost associated with traditional prototyping methods.

- Cost reduction: With 3D printing, you can eliminate the need for expensive molds or tooling, resulting in significant cost savings, especially for small batch production.

- Customization options: 3D printing enables the creation of highly customized and personalized products, tailored to specific customer requirements.

- Complex design capabilities: 3D printing unlocks the ability to produce intricate and complex designs that would be challenging or impossible to achieve using traditional manufacturing techniques.

In addition to these benefits, 3D printing also supports small-scale production, making it a viable option for niche markets or limited production runs. The technology offers flexibility, efficiency, and the ability to bring ideas to life in a cost-effective manner. Whether it’s for prototyping, customization, or complex designs, 3D printing opens up a world of possibilities for various industries and applications.

Tips for Improving Print Quality

To improve the quality of your 3D prints, start by calibrating your printer settings. Proper printer calibration ensures accurate and precise filament deposition, leading to higher-quality prints. Additionally, regular nozzle maintenance is essential for consistent print quality. Clogged or jammed nozzles can result in poor filament flow and uneven extrusion. Cooling techniques also play a crucial role in print quality. Implementing proper cooling methods helps prevent overheating and improves the overall finish of your prints. Another factor to consider is print bed adhesion. Ensuring proper adhesion between the print bed and the filament is crucial for preventing warping and achieving a strong foundation for your prints. Lastly, using high-quality filament is key to achieving excellent print quality. Low-quality filament can lead to inconsistencies and poor layer adhesion. By focusing on printer calibration, nozzle maintenance, cooling techniques, print bed adhesion, and filament quality, you can significantly improve the overall quality of your 3D prints.

| Tips for Improving Print Quality |

|:—:|:—:|:—:|

| Printer Calibration | Nozzle Maintenance | Cooling Techniques |

| – Ensure accurate and precise filament deposition | – Regularly clean and unclog the nozzle | – Implement proper cooling methods |

| – Prevent poor extrusion and uneven printing | – Use a soft metal brush or compressed air | – Prevent overheating and improve print finish |

| – Achieve consistent and high-quality prints | – Avoid damaging the nozzle with side cutters | – Optimize cooling settings in slicer software |

| – Follow online tutorials for proper calibration | – Prevent poor print quality due to nozzle issues | – Experiment with different cooling fan speeds |

| – Calibrate Z offset for proper nozzle height | – Maintain a well-functioning nozzle for optimal prints | – Find the right balance between cooling and print speed |

| – Ensure proper bed leveling for uniform prints | – Prevent filament clogs and jams for consistent extrusion | – Proper cooling techniques improve print quality |

| – Achieve strong foundation for prints | – Achieve consistent and accurate prints | – Avoid overheating and warping issues |

| – Use high-quality filament for better print quality | – Improve overall print quality and layer adhesion | – Achieve consistent and clean print finishes |

Applications of 3D Printing

The versatility of 3D printing finds its application across various industries and sectors, revolutionizing the way we approach manufacturing and design.

- Customization potential: 3D printing allows for the creation of highly customized products, tailored to individual needs and preferences. This opens up new possibilities in industries such as healthcare, where personalized prosthetics and implants can be created.

- Environmental impact: 3D printing has the potential to reduce waste and energy consumption compared to traditional manufacturing methods. It enables on-demand production, eliminating the need for mass production and reducing excess inventory.

- Industrial applications: 3D printing is being increasingly used in industries such as aerospace and automotive for rapid prototyping, lightweight component production, and tooling. It offers faster turnaround times and cost savings.

- Art and design: 3D printing has given artists and designers new tools and techniques to explore. It allows for the creation of intricate and complex designs that were previously difficult to achieve.

- Education sector: 3D printing has become a valuable tool in the education sector, enabling students to learn through hands-on experience. It allows for the creation of teaching aids, models, and prototypes, enhancing the learning process.

The applications of 3D printing are vast and continue to expand as technology advances. Its customization potential, environmental impact, industrial applications, and relevance in art and design and the education sector make it a game-changer in various fields.

Materials Used in 3D Printing

Materials play a crucial role in the success of 3D printing projects, allowing you to bring your designs to life with precision and durability. When it comes to 3D printing, filament selection is a key consideration. Different materials have unique properties that can affect the printing process and the final outcome of your prints. Understanding the material properties is essential for achieving the desired results. Additionally, proper filament storage is important to maintain the quality of your filament. Moisture absorption can lead to issues such as warping and poor print quality. Consider using a dry box or filament dryer to keep your filament dry and in optimal condition. In some cases, filament drying may be necessary before printing. Filament diameter calibration is another crucial step in the process. Ensuring that the filament diameter is accurately calibrated is essential for achieving accurate prints. Use a caliper or filament diameter measurement tool to check and adjust the filament diameter if needed. By carefully selecting your filament, understanding material properties, properly storing and drying filament, and calibrating filament diameter, you can enhance the quality and success of your 3D printing projects.

Future Trends in 3D Printing

Embrace the exciting potential of future advancements in 3D printing technology. The future of 3D printing holds several promising trends that will revolutionize various industries.

- Advancements in multi-material printing: The ability to print objects with multiple materials opens up new possibilities for creating complex and functional designs. This advancement allows for the integration of different properties, such as flexibility and rigidity, within a single object.

- Integration of 3D printing with robotics, AI, and space exploration: The combination of 3D printing with robotics and artificial intelligence enables automated and efficient production processes. This integration can lead to advancements in space exploration, where 3D printing can be used to fabricate tools and structures in remote environments.

- Biodegradable and sustainable materials in 3D printing: The use of biodegradable and sustainable materials in 3D printing aligns with the growing demand for environmentally friendly practices. These materials offer a more sustainable alternative to traditional plastics and contribute to reducing the environmental impact of 3D printing.

- Expansion of 3D printing in the construction industry: 3D printing is poised to revolutionize the construction industry by enabling the rapid and cost-effective production of complex architectural structures. This technology has the potential to streamline construction processes, reduce waste, and introduce innovative design possibilities.

- Adoption of 3D printing in the healthcare and medical field: 3D printing is already making significant contributions to the healthcare and medical field. It enables the production of customized implants, prosthetics, and surgical models, improving patient outcomes and reducing costs. The use of 3D printing in this industry is expected to continue growing, leading to further advancements in personalized medicine and medical research.