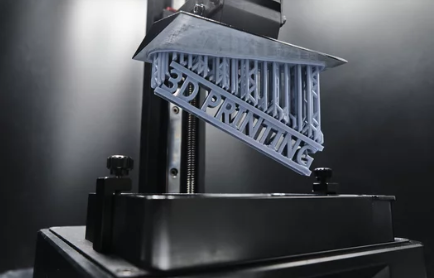

Are you curious about how 3D printing is revolutionizing industries and propelling us into the future? Look no further! In this article, we’ll explore the exciting advancements in 3D printing technology, focusing on its impact in the aerospace industry. Imagine rocket components manufactured with unprecedented speed and precision, spare parts printed on-demand in outer space, and human colonization of other planets becoming a reality. But the implications of 3D printing extend beyond space travel. From personalized medicine to sustainable construction, this technology is transforming everyday life in unimaginable ways. Let’s dive in!

3D Printing in Various Industries

In various industries, 3D printing is revolutionizing manufacturing processes and pushing the boundaries of innovation. This technology is making waves in customized fashion, sustainable food, lightweight vehicles, personalized healthcare, and advanced aerospace components. In the fashion industry, designers are utilizing 3D printing to create unique clothing and accessories, allowing for endless possibilities in design and personal expression. Additionally, 3D printing is being used to create customized and perfectly fitted clothing, enhancing comfort and functionality. In the food industry, 3D printing is enabling the creation of tailored meals that cater to specific dietary needs and preferences. This technology is also being employed to produce complex and artistic food designs, enhancing dining experiences and promoting food safety.

In the automotive sector, 3D printing is revolutionizing the production of lightweight and durable parts, resulting in more efficient and personalized vehicles. Moreover, in the field of healthcare, 3D printing is transforming personalized medical solutions, such as custom-fit prosthetics and dental implants, improving the quality of life for patients. Lastly, in the aerospace industry, 3D printing is playing a crucial role in the creation of advanced components with complex geometries, leading to improved fuel efficiency and performance. Overall, 3D printing is paving the way for innovation and customization across various industries.

3D Printing in Aerospace

3D printing revolutionizes aerospace manufacturing by transforming the production of aircraft components. With its ability to create complex geometries and lightweight structures, 3D printing offers numerous advantages for the aerospace industry. The future applications of this technology in space exploration are promising, as it can facilitate the manufacturing of spare parts, satellite production, and even the construction of habitats on the moon and Mars. Startups like Relativity are already leveraging 3D printing to accelerate rocket production, reducing costs and improving manufacturing efficiency.

Additionally, research on 4D printing in aerospace has shown potential for improved performance and fuel efficiency of drone wings. By utilizing 3D printing technology, space travel can become more accessible and sustainable, as it reduces the need for carrying spare parts and enables repairs and modifications on-the-go. Ultimately, 3D printing in aerospace holds the potential to revolutionize the industry by lowering costs, enhancing manufacturing efficiency, and creating lightweight structures that improve fuel efficiency and overall performance.

Implications of 3D Printing Technology on Everyday Life

By revolutionizing aerospace manufacturing, 3D printing not only holds immense potential for the industry, but also has far-reaching implications on everyday life. From personalized healthcare to customized fashion, sustainable transportation to advanced architectural designs, and even culinary creations, 3D printing is reshaping various sectors and transforming the way we live.

1. Personalized healthcare: With 3D printing, medical solutions can be customized to fit individual needs. This includes personalized prosthetics, dental implants, and even organs and tissues that can be printed using biocompatible materials.

2. Customized fashion: 3D printing is enabling fashion designers to create unique and perfectly fitted clothing and accessories. From intricate and complex designs to sustainable and recycled materials, the possibilities for personalized fashion are endless.

3. Sustainable transportation: The use of 3D printing in the transportation industry allows for the production of lightweight and durable parts, resulting in more efficient and personalized vehicles. This not only improves fuel efficiency but also reduces the environmental impact of transportation.

In addition to these examples, 3D printing is also revolutionizing advanced architectural designs and introducing new culinary creations. As this technology continues to advance, the implications on everyday life will only continue to grow, leading to a more personalized, sustainable, and innovative future.

Implications of 3D Printing Technology on Space Travel

With 3D printing technology, you can revolutionize space travel and its capabilities. Printing in space opens up a world of possibilities for sustainable space missions. Imagine being able to create spare parts on demand, reducing the need for carrying extra supplies and minimizing waste. 3D printing also enables the building of habitats on other celestial bodies, such as the moon or Mars. This could significantly reduce the costs and resources required for long-duration space missions, making colonization of other planets a viable option.

Additionally, 3D printing allows for repairs and modifications in space travel, ensuring the success of missions and extending the lifespan of spacecraft. The ability to manufacture necessary components on-site eliminates the need for costly and time-consuming resupply missions. As we continue to explore the cosmos, 3D printing technology will play a crucial role in advancing space travel and making it more sustainable and efficient.

Advantages of 4D Printing in Various Industries

You can further explore the potential of additive manufacturing technology by understanding the advantages of 4D printing in various industries. 4D printing offers unique benefits beyond traditional 3D printing, particularly in applications where an electric current is applied. Here are three advantages of 4D printing in different sectors:

1. **Energy efficient devices**: 4D printing allows for the creation of dynamic structures that can change shape and function according to needs. This capability can lead to the development of energy-efficient devices, such as self-adjusting solar panels or wind turbines that optimize their shape to capture maximum energy.

2. **Lightweight structures**: Industries like aerospace and transportation can benefit from 4D printing’s ability to create lightweight and flexible structures. Lightweight components can improve fuel efficiency in vehicles and reduce the overall weight of aircraft, resulting in safer and more sustainable transportation options.

3. **Sustainable transportation**: By utilizing 4D printing, the transportation industry can improve aerodynamics and fuel efficiency. Dynamic structures can adapt to changing environmental conditions, reducing drag and optimizing performance. This advancement in technology can lead to the development of more sustainable vehicles and contribute to a greener future.

Future Prospects of 3D Printing Technology

The future of 3D printing holds immense potential for advancements in various industries, including aerospace, fashion, healthcare, and transportation. As this technology continues to evolve, it is expected to bring about significant changes in our everyday lives. One of the key prospects of 3D printing is the democratization of the technology, making it more accessible and user-friendly. Imagine a future where anyone can easily operate a 3D printer, just like operating an office inkjet printer. This can revolutionize industries by enabling individuals and small businesses to bring their ideas to life, fostering innovation and creativity.

Enhanced personalization is another exciting prospect of 3D printing. The ability to create customized and tailored products has the potential to transform various sectors. In fashion, for example, 3D printing allows for perfectly fitted, customized clothing and accessories, enabling individuals to express their personal style in a unique way. The concept of dynamic structures in 4D printing further enhances personalization by creating objects that can change and adapt according to specific needs. This opens up possibilities for creating products that are not only aesthetically pleasing but also functional and responsive.

Sustainability is also an important aspect of the future of 3D printing. With the ability to produce objects on-demand and in a localized manner, 3D printing has the potential to reduce waste, energy consumption, and carbon emissions. This can have a significant impact on everyday life, from reducing the need for mass-produced products and packaging to promoting the use of sustainable materials and recycling.

In the aerospace industry, 3D printing is already revolutionizing manufacturing processes. It allows for the creation of complex geometries and lightweight structures, improving fuel efficiency and performance. Advancements in aerospace manufacturing through 3D printing can lead to more efficient aircraft, reduced costs, and increased exploration of space. Startups like Relativity are already accelerating rocket production using 3D printing technology, pushing the boundaries of what is possible in space travel.

Medical Innovations

In the article ‘Rocketing Ahead With 3D Printing: Innovations and Developments’, let’s now delve into the subtopic of ‘Medical Innovations’ and explore the groundbreaking advancements in this field.

1. Customized prosthetics: With 3D printing, prosthetics can be tailor-made to fit individual patients, improving comfort and functionality. This technology enables the creation of prosthetic limbs that closely resemble natural ones, providing a sense of normalcy for amputees.

2. Surgical advancements: 3D printing allows surgeons to create precise surgical guides and models, enhancing preoperative planning and reducing surgical risks. This technology enables surgeons to better visualize complex procedures, leading to improved surgical outcomes.

3. Organ transplantation: The shortage of organs for transplantation is a major challenge in healthcare. 3D printing offers the potential to create functional organs using a patient’s own cells, eliminating the need for donors and reducing the risk of rejection. This could revolutionize the field of organ transplantation and save countless lives.

Furthermore, 3D printing has applications in dental medicine, where it is used to create custom-fit dental implants and prosthetics. Additionally, it is being explored for the development of drug delivery systems, allowing for personalized medication dosages and targeted therapies.

The advancements in 3D printing technology have the potential to revolutionize the medical field, improving patient care, and transforming the way healthcare professionals approach treatment and surgery. With further developments and research, the possibilities for medical innovations using 3D printing are limitless.

Aerospace Advancements

With 3D printing technology, aerospace advancements have reached new heights, transforming the manufacturing of aircraft components and revolutionizing the way we explore outer space. The use of 3D printing in the aerospace industry allows for the creation of lightweight components, complex geometries, and rapid prototyping. The ability to produce lightweight components is particularly beneficial in aerospace, as it improves fuel efficiency and performance.

Complex geometries that were previously difficult to manufacture can now be easily achieved with 3D printing, opening up new possibilities for design and innovation. Rapid prototyping allows for faster iteration and testing of new ideas, reducing development time and costs. Additionally, 3D printing is used in the aerospace industry for tooling and fixtures, providing efficient and cost-effective solutions. By reducing manufacturing costs and enabling the production of intricate and lightweight parts, 3D printing is revolutionizing the aerospace industry and pushing the boundaries of what is possible in space exploration.

Automotive Innovations

Get ready to witness the incredible automotive innovations made possible by 3D printing technology. With the ability to create customized automotive parts, lightweight vehicle structures, and fuel efficiency improvements, 3D printing is revolutionizing the automotive industry. Rapid prototyping in automotive has never been easier, allowing manufacturers to quickly iterate and test their designs. Additionally, 3D printing has reduced production time in the automotive sector, enabling faster delivery of vehicles to customers.

1. Customized automotive parts: With 3D printing, car manufacturers can now produce personalized and tailored parts for their customers. From customized interior trims to unique exterior accessories, the possibilities are endless.

2. Lightweight vehicle structures: 3D printing allows for the creation of complex and lightweight structures, resulting in vehicles that are more fuel-efficient and agile. By reducing the weight of vehicles, manufacturers can also improve overall performance and handling.

3. Fuel efficiency improvements: With the ability to create lightweight parts and optimize designs, 3D printing is helping to improve fuel efficiency in the automotive industry. By reducing the weight of vehicles and minimizing aerodynamic drag, cars can achieve better mileage and lower emissions.

As the automotive industry continues to embrace 3D printing technology, we can expect to see even more advancements in customized parts, lightweight structures, fuel efficiency improvements, rapid prototyping, and reduced production time. The possibilities for innovation are limitless, and the future of the automotive industry looks promising with 3D printing at the forefront.

Architecture and Construction

As you explore the world of 3D printing technology, you will frequently encounter its remarkable applications in the field of architecture and construction. The use of 3D printing in these industries has opened up new possibilities and revolutionized traditional construction methods. One of the most exciting advancements is the ability to create 3D printed buildings. This innovative technique allows for the construction of structures using sustainable construction materials, which reduces the environmental impact of the building process.

Additionally, 3D printing enables a faster construction process compared to traditional methods, saving time and resources. The technology also allows for the creation of complex architectural designs that were previously difficult to achieve. With 3D printing, architects can bring their intricate and imaginative designs to life. Moreover, the use of 3D printing in construction leads to reduced construction waste, as the technology allows for precise material usage. This not only contributes to a more sustainable construction industry but also helps reduce costs. Overall, the integration of 3D printing in architecture and construction has the potential to transform the industry, offering faster, more sustainable, and highly customizable building methods.