Rough edges can not only detract from the overall aesthetic appeal but also impact the functionality of the project.

Here, we’ll explore effective techniques for smoothing those pesky rough edges and corners. By adjusting factors such as printing temperature, speed, and calibration, you can achieve smoother results.

We’ll also discuss the importance of choosing the right filament and provide tips for successful smoothing. So, get ready to elevate the appearance, surface finish, and durability of your 3D prints with these expert techniques.

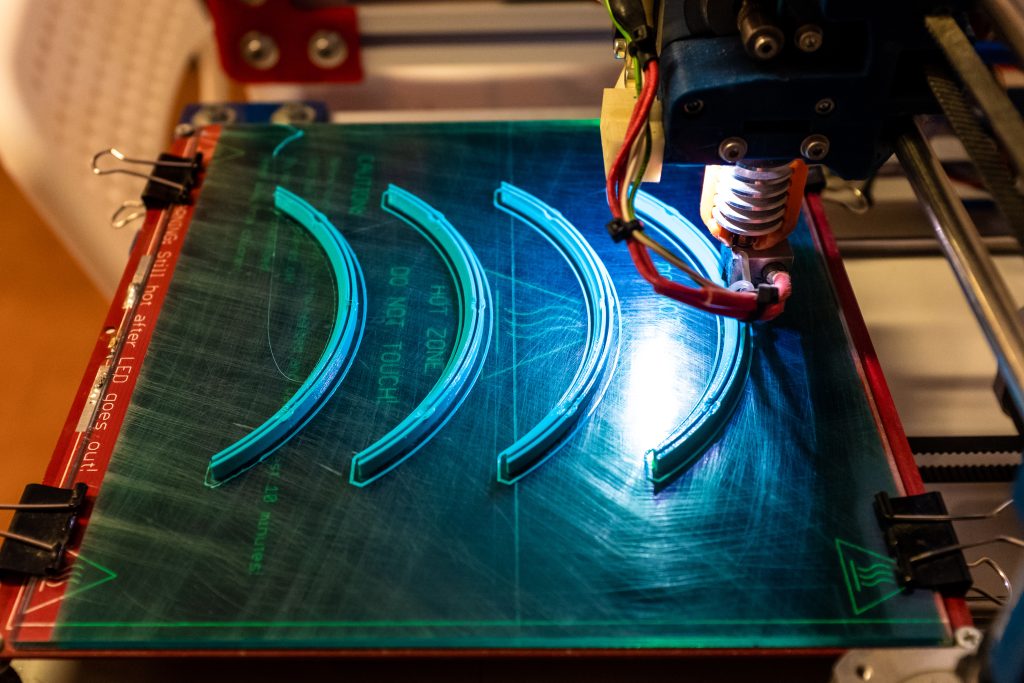

Common Causes of Rough Edges on 3D Prints

The major causes of rough edges on 3D prints include printing at high temperatures, printing too fast, inaccurate z-offset and print bed calibration, printing thin objects, and using filaments prone to the issue. The impact of cooling and temperature control on rough edges cannot be overstated.

- Insufficient cooling can result in rough corners and edges. It is important to have efficient cooling mechanisms in place, such as a fan duct or a stronger fan, to improve the overall print quality.

- Additionally, proper temperature control is crucial for achieving smooth edges. Consistent operating temperature helps ensure that the layers cool and solidify uniformly, minimizing the occurrence of rough edges.

- Exploring the benefits of PLA smoothing, it is evident that smoothing PLA prints can give them a polished and professional look.

- It enhances the surface finish and eliminates roughness, resulting in aesthetically pleasing prints.

- Smoothing also improves the strength and durability of PLA prints, making them more resistant to wear and tear.

- Moreover, it allows for better post-processing and painting options, enabling users to achieve their desired final appearance.

Methods For Smoothing

There are different methods for smoothing PLA prints.

- Sanding is a common technique that involves using abrasive materials to remove layer lines.

- Chemical smoothing using solvents like acetone or ethyl acetate can also be effective, but precautions should be taken, such as ensuring proper ventilation.

- Heat treatment with a heat gun or oven can be used to smooth PLA prints.

- Another method is using epoxy or resin coatings to create a smooth finish. Mechanical polishing with abrasive compounds is another option.

Precautions when PLA smoothing

When considering PLA smoothing, there are precautions and considerations to keep in mind.

- Proper ventilation is important when using chemicals for smoothing.

- Some smoothing techniques may weaken the structural integrity of PLA prints, so it’s essential to follow safety guidelines.

- Different PLA filaments may require different smoothing methods, so experimentation and testing are recommended to achieve the desired results.

Guidelines for successful PLA smoothing techniques

- To ensure successful PLA smoothing techniques, start with a well-printed and clean PLA object.

- Gradually increase the grit size when sanding PLA prints for better results.

- Applying multiple coats of smoothing agents can help achieve a smoother finish.

- It is also advisable to test the smoothing method on a small area before applying it to the entire print.

- Regularly inspect and clean the smoothing tools to avoid contamination and maintain their effectiveness.

By following these tips, users can achieve smooth and professional-looking PLA prints.

Effective Methods for Lowering Printing Temperature

To achieve smoother corners on your 3D prints, try gradually lowering the printing temperature until you get perfect results.

Here are some effective methods for lowering the printing temperature:

Increasing layer adhesion

By reducing the printing temperature, you can improve the adhesion between the layers, resulting in smoother corners.

Optimizing cooling settings

Adjusting the cooling settings on your 3D printer can help regulate the temperature and prevent overheating, which can cause rough edges.

Experiment with different cooling fan speeds and layer fan settings to find the optimal cooling for your prints.

Experimenting with different infill patterns

The infill pattern can affect the overall strength and appearance of your prints. By experimenting with different infill patterns, such as honeycomb or gyroid, you can achieve smoother corners and reduce the chances of rough edges.

Using a heat resistant bed surface

A heat resistant bed surface, such as a glass plate or a PEI sheet, can help maintain a stable printing temperature and prevent warping. This, in turn, can contribute to smoother corners on your prints.

Exploring alternative printing techniques

If you’re still experiencing rough corners, it may be worth exploring alternative printing techniques, such as using a different printing method like resin or SLA. These methods often produce smoother prints with minimal post-processing required.

Techniques for Decreasing Printing Speed

For smoother corners on your 3D prints, try decreasing the printing speed to allow for better cooling and solidification between layers. Slowing down the print speed gives each layer more time to cool before the next layer is added, reducing the chances of rough edges and corners.

Additionally, adjusting the cooling settings can help improve the overall print quality. Increasing the cooling fan speed or using a fan duct can enhance the cooling efficiency, preventing overheating and promoting better layer adhesion.

Optimizing acceleration settings can also contribute to smoother corners. By fine-tuning the acceleration values in your printer’s firmware, you can ensure that the printer moves smoothly and accurately, reducing the chances of jerky movements that can lead to rough edges.

Using support structures can provide additional stability and prevent sagging or warping, resulting in cleaner corners. Experimenting with different infill patterns can also help improve the overall strength and stability of the print, reducing the likelihood of rough edges and corners.

Importance of Proper Print Bed and Z-Offset Calibration

Proper print bed and z-offset calibration can ensure accurate and smooth corners on your 3D prints. Achieving precise calibration is essential for achieving high-quality prints.

Here are some calibration tips to help you troubleshoot and improve your printing process:

Significance of Calibration

Calibration ensures that the print bed is level and the nozzle is at the correct height from the bed, allowing for proper adhesion and layer deposition. This precision is crucial for achieving smooth corners and overall print accuracy.

Calibration Tips

Start by leveling the print bed using the appropriate method for your printer. Use a calibration tool or paper to ensure the correct nozzle height. Make small adjustments to the z-offset until the first layer adheres properly. Regularly check and recalibrate as needed for consistent results.

Troubleshooting

If you’re experiencing rough corners, check your calibration first. Uneven or incorrect bed leveling, as well as an incorrect z-offset, can lead to rough edges. Revisit the calibration process and make any necessary adjustments to improve print quality.

Best Practices

Follow the manufacturer’s guidelines for bed leveling and z-offset calibration. Use a reliable calibration tool for accurate measurements. Take your time during the calibration process to ensure precision. Regularly recalibrate, especially after making any changes to your printer or print settings.

Importance of Precision

Precision in print bed and z-offset calibration directly impacts the quality of your prints, particularly the corners. Accurate calibration ensures proper layer adhesion, prevents warping, and promotes smooth and precise corner formation.

Choosing the Right Filament for Smoother Prints

When choosing the right filament, consider the properties of different materials to achieve smoother prints. Filament properties play a crucial role in determining the surface finish of your 3D prints. PLA filament, for example, tends to produce smoother prints compared to ABS filament.

Additionally, consider the compatibility of the filament with your 3D printer. Ensure that the filament is compatible with your printer’s extruder temperature and nozzle size to optimize print quality. Filament surface finish also affects the smoothness of prints. Look for filaments that have a consistent diameter and low deviation to avoid inconsistencies in the print.

Filaments with good cooling requirements are beneficial for achieving smoother prints. Look for materials that cool down and solidify quickly to minimize the chances of warping or rough edges.

Lastly, consider the availability of the filament. Choose filaments that are readily available and have a proven track record of producing smooth prints. By carefully considering these factors, you can select the right filament for smoother and high-quality 3D prints.