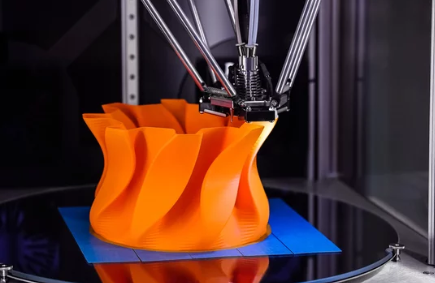

Are you ready to unlock the ABS advantage and enhance your 3D printing experience? Look no further! In this article, we’ll delve into the world of Acrylonitrile Butadiene Styrene (ABS) and discover why it’s a popular choice in the industry. With its affordability and desirable properties, such as strength, durability, and temperature resistance, ABS is suitable for a variety of applications. We’ll explore material properties, optimal printing settings, supports and dual extrusion, as well as storage and handling considerations. Let’s dive in and explore the ABS advantage!

Properties of ABS Material

When considering the properties of ABS material, you can rely on its excellent impact resistance, good tensile strength, and moderate glass transition temperature. ABS exhibits exceptional resistance to impact, making it suitable for applications that require durability and strength. It also possesses good tensile strength, allowing it to withstand tension and stretching forces. The moderate glass transition temperature of ABS ensures stability at high temperatures, making it a reliable choice for various environments.

In addition to its mechanical properties, ABS also offers other desirable characteristics. It demonstrates chemical resistance, making it resistant to a wide range of chemicals and solvents. ABS provides a smooth surface finish for printed objects, resulting in high-quality and visually appealing prints. Furthermore, ABS has moderate UV resistance, allowing it to withstand exposure to sunlight without significant degradation.

ABS 3D Printing Settings

To optimize the printing process and ensure successful outcomes, it is essential to carefully adjust and fine-tune ABS 3D printing settings. Here are three key factors to consider:

1. **Print bed temperature optimization**: Setting the print bed temperature between 90°C to 110°C is crucial for preventing warping and ensuring proper adhesion. This temperature range allows the ABS material to adhere to the bed surface effectively.

2. **Extruder temperature impact**: The extruder temperature should be set between 220°C to 250°C for effective filament melting and deposition. Adjusting the temperature within this range ensures that the ABS filament is melted properly and extruded smoothly.

3. **Rafts for first layer success**: Adding rafts beneath the print can significantly improve the success of the first layer. Rafts provide a larger surface area for the initial layers to adhere to, reducing the chances of warping or detachment.

In addition to these settings, it is recommended to use enclosed printers or DIY enclosures. These help maintain a consistent temperature throughout the printing process, preventing warping caused by temperature fluctuations. Moreover, ABS parts work well with HIPS supports for dual extrusion printing. HIPS supports can be dissolved using d-Limonene for clean removal, allowing for the design of more complex overhanging structures. By optimizing these settings and considering the use of supports and enclosures, you can achieve successful ABS 3D prints with minimal warping and high-quality results.

ABS Supports and Dual Extrusion

To optimize ABS 3D printing settings and achieve successful outcomes, it is important to understand the use of ABS supports and dual extrusion. ABS parts work well with HIPS (High Impact Polystyrene) supports for dual extrusion printing. HIPS supports are compatible with ABS and can be easily dissolved using a solvent like d-Limonene, leaving behind clean and smooth surfaces. This makes it possible to print complex structures with overhangs that would otherwise be difficult to achieve. Dual extrusion techniques allow for the simultaneous printing of both ABS and HIPS materials, enabling the creation of intricate designs and functional prototypes.

By using ABS as the primary material and HIPS as the support material, it is possible to print objects with complex geometries and internal cavities. The HIPS supports can be easily removed by dissolving them in d-Limonene, resulting in a clean and finished ABS part. This combination of ABS and HIPS compatibility, soluble supports, and dual extrusion techniques opens up new possibilities for creating complex and intricate 3D printed objects with ABS.

Storage and Handling of ABS

For effective storage and handling of ABS, it is essential to prioritize proper filament storage and maintenance. ABS is hygroscopic, meaning it can absorb moisture from the environment, which can lead to print quality issues. To prevent moisture absorption and ensure optimal printing results, here are three key steps to follow:

1. Filament Drying: If ABS filament has absorbed moisture, it is crucial to dry it before use. This can be done using a filament dryer or a low-temperature oven. Proper drying helps eliminate any moisture present in the filament, ensuring better print quality and adhesion.

2. Airtight Storage: ABS filament should be stored in a cool, dry place to minimize exposure to moisture. It is best to store ABS in an airtight container to provide an additional layer of protection against humidity and moisture in the air. This helps maintain the filament’s quality and prevents it from absorbing moisture.

3. Desiccant Packets: To further prevent moisture absorption, desiccant packets can be added to the filament storage container. Desiccant packets contain moisture-absorbing agents that help keep the filament dry and free from moisture. Regularly checking and replacing these packets is important to ensure their effectiveness in maintaining filament quality.

Introduction to Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic material commonly used in both injection molding and 3D printing processes. ABS is a copolymer composed of acrylonitrile, butadiene, and styrene, which gives it a balance of strength, toughness, and processability. The manufacturing process of ABS involves either an emulsion technique or continuous mass technique. ABS has a non-crystalline structure and is known for its high strength and high toughness.

It has a low melting point, making it suitable for 3D printing. ABS is commonly available in an opaque ivory color, but it can also be colored with pigments or dyes to offer a wide range of color options. One of the advantages of ABS is that it can be recycled through various methods such as mechanical recycling and chemical recycling. Understanding the material composition, melting point, color options, and recycling methods of ABS is crucial for its successful application in both injection molding and 3D printing processes.

Advantages of ABS Material

When considering ABS material for 3D printing, you’ll find numerous advantages that make it a top choice in the industry. Here are three key advantages of ABS material:

1. Versatility: ABS is known for its versatility in manufacturing processes, allowing for the creation of complex geometries and intricate designs. Its high strength and durability make it suitable for a wide range of applications, from prototyping to end-use parts. ABS also offers good dimensional stability, making it ideal for functional parts that require precise measurements.

2. Design Flexibility: ABS material provides designers with a great deal of freedom when it comes to design considerations. It can be easily machined, drilled, sanded, and painted, allowing for post-processing techniques to achieve the desired surface finish and appearance. ABS also has good adhesion properties, making it compatible with various bonding methods, such as solvent welding or adhesive bonding.

3. Comparison with Other Materials: When compared to other 3D printing materials, ABS stands out for its balance of properties. It offers excellent impact resistance and good tensile strength, making it suitable for applications that require durability. ABS also has good chemical resistance and moderate UV resistance, making it suitable for outdoor applications. Additionally, ABS is more affordable compared to materials like nylon or polycarbonate, making it a cost-effective choice for many projects.

Applications of ABS Material

One of the key applications of ABS material in 3D printing is its use in printing cases, project enclosures, and automotive parts. ABS is a versatile material that finds its place in various industries, including aerospace, consumer electronics, medical devices, automotive, and architectural models.

| ABS Material Applications | Examples |

|---|---|

| Aerospace | Prototyping, tooling |

| Consumer Electronics | Phone cases, camera accessories |

| Medical Devices | Surgical instruments, prosthetics |

| Automotive Industry | Interior components, dashboard parts |

| Architectural Models | Scale models, building prototypes |

ABS material is favored in the aerospace industry for prototyping and tooling applications due to its strength, durability, and temperature resistance. In consumer electronics, ABS is commonly used for printing phone cases and camera accessories. In the medical field, ABS is utilized for producing surgical instruments and prosthetics.

The automotive industry benefits from ABS by printing interior components and dashboard parts. Lastly, ABS material is employed in architectural models for creating scale models and building prototypes. With its wide range of applications, ABS material continues to prove its value in the 3D printing industry.

Mechanical and Thermal Properties of ABS Material

The mechanical and thermal properties of ABS material greatly contribute to its versatility and wide range of applications in the 3D printing industry. ABS exhibits excellent mechanical strength, making it suitable for various demanding applications. It also offers good thermal stability, allowing it to withstand high temperatures without compromising its structural integrity. Additionally, ABS material possesses exceptional impact resistance, ensuring that printed objects can withstand external forces without breaking or cracking.

Here are three key properties of ABS material:

1) Dimensional stability: ABS has good dimensional stability, meaning that it maintains its shape and size even under varying temperature and humidity conditions. This makes it ideal for applications where precision and accuracy are essential.

2) Weather resistance: While ABS is not as weather-resistant as some other materials, it still exhibits moderate resistance to UV radiation and changing weather conditions. However, prolonged exposure to sunlight can cause ABS to change color and become brittle over time.

3) Heat distortion temperature: ABS has a heat distortion temperature ranging from around 70°C to 107°C. This temperature range defines the point at which ABS begins to soften and lose its structural integrity. To enhance its heat resistance, ABS can be annealed, resulting in an increase in its heat distortion temperature by about 10°C.

Understanding the mechanical and thermal properties of ABS material is crucial for optimizing 3D printing processes and selecting the right material for specific applications.

Electrical and Environmental Properties of ABS Material

To understand the electrical and environmental properties of ABS material, it is important to consider its resistance to various factors. ABS exhibits good electrical insulation, making it suitable for applications that require electrical components. It is hardly affected by temperature, humidity, and frequency, allowing it to be used in most environments for 3D printing. ABS also displays certain toughness at -40°C, enabling its use in a wide temperature range from -40°C to 85°C.

In terms of chemical resistance, ABS is not affected by water, inorganic salts, alkali alcohols, and hydrocarbon solvents. However, it can be dissolved in ketones, aldehydes, and chlorinated hydrocarbons. ABS demonstrates excellent wear resistance and impact absorption, contributing to its high durability. Furthermore, ABS is not biodegradable, making it a long-lasting material. These electrical and environmental properties make ABS a versatile choice for various applications, including electrical components, automotive parts, and even sports equipment. Its ability to withstand different factors ensures its reliability and environmental durability.

Application Tips for ABS Material in 3D Printing

When printing with ABS material, it is important to keep these application tips in mind for a successful 3D printing experience:

1. Heating Techniques: ABS has a higher tendency to warp compared to other materials, so proper heating techniques are crucial. Preheating the print bed to a temperature between 90°C to 110°C can prevent warping and ensure proper adhesion. Additionally, using an enclosed printer or DIY enclosure can help maintain a consistent temperature and further prevent warping.

2. Surface Preparation: ABS requires surface preparation to enhance adhesion. Applying a thin layer of adhesive, such as ABS/acetone blends or hair spray, can prevent upward curling on the printed surface. Proper surface preparation ensures better print quality and reduces the chances of print failures.

3. Post-processing Techniques: After printing with ABS, post-processing techniques can be employed to improve the final result. For example, smoothing the surface with acetone vapor can provide a glossy finish. Additionally, sanding and painting can further enhance the aesthetic appeal of ABS prints.