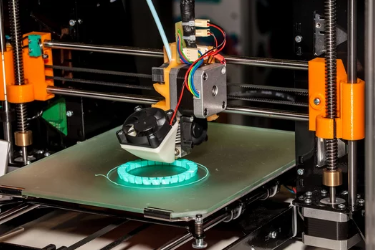

Do you love building with Lego? Imagine being able to create your own custom Lego pieces and minifigures, bringing your wildest brick-building dreams to life. With 3D printing technology, this is now possible. In this article, we’ll explore the exciting world of 3D printing Lego pieces and the endless possibilities it brings to your Lego creations. You’ll learn how to design personalized minifigures, create unique Lego pieces, and even replace missing or broken parts. Get ready to unleash your imagination and embark on a journey into the fun side of 3D printing with Lego.

Benefits of 3D Printing Lego Pieces

One of the benefits of 3D printing Lego pieces is that it allows you to create personalized designs that are not available in standard sets. With 3D printing, you have endless customization options. You can design and print your own unique Lego pieces, giving you the freedom to create whatever you can imagine. This level of customization is not possible with traditional Lego sets.

Another benefit of 3D printing Lego pieces is the cost effectiveness. Printing Lego pieces at home can be more affordable than purchasing individual pieces or sets. You can save money by printing the specific pieces you need instead of buying entire sets. Additionally, 3D printing technology has become more accessible to the general public. There are affordable 3D printers available on the market, and the process of printing Lego pieces has become easier and more user-friendly.

3D printing Lego pieces also has educational value. It can be a fun and educational activity for children to learn about design and engineering. They can learn how to create their own designs, understand the principles of 3D printing, and see their creations come to life.

Furthermore, 3D printing can be used to create replacement parts for your Lego sets. If you have missing or broken pieces, you can simply print new ones instead of having to buy a whole new set. This saves money and reduces waste.

Materials and Tools for 3D Printing

To start 3D printing Lego pieces, you’ll need a few essential materials and tools. Here are the key items you’ll need:

1. PLA filament: PLA is a commonly used filament material for 3D printing Lego pieces due to its durability and ease of use. It’s important to choose high-quality PLA filament that is compatible with your 3D printer.

2. 3D modeling software: Designing Lego pieces requires the use of 3D modeling software to create the desired shapes and dimensions. There are various software options available, both free and paid, that provide the necessary tools for designing Lego pieces.

3. 3D printer: A 3D printer is necessary to bring the digital designs to life by printing the Lego pieces layer by layer. It’s important to choose a reliable and compatible 3D printer that can handle the size and complexity of your Lego designs.

In addition to these materials, there are a few other tools that can enhance the 3D printing process:

– Print bed adhesion: Proper adhesion to the print bed is crucial to ensure the quality and accuracy of the 3D printed Lego pieces. Using adhesive materials or a heated print bed can help improve adhesion.

– Finishing tools: After printing, you may need to smooth and finish the 3D printed Lego pieces for a polished look. Sandpaper, files, and paint can be used to remove any imperfections and enhance the appearance of the finished pieces.

Tips and Techniques for 3D Printing

When printing Lego pieces, it’s important to consider certain tips and techniques to ensure successful and high-quality results. First, layer height optimization is crucial for achieving the desired level of detail and strength in your 3D printed Lego pieces. Adjusting the layer height and print settings can greatly impact the overall quality of the final product. Additionally, support structures may be necessary for complex designs to maintain stability during the printing process. However, it’s important to remove these support structures carefully after printing to avoid any damage to your Lego pieces.

Post processing techniques, such as sanding and painting, can be used to enhance the appearance of your 3D printed Lego creations. It’s also recommended to perform test prints and troubleshoot any issues or improvements before printing the complete design. Lastly, when designing interlocking mechanisms for your Lego pieces, ensure proper tolerances and fit to ensure a secure connection between the printed parts. By following these tips and techniques, you can create high-quality, customized Lego pieces using 3D printing technology.

Inspiration and Resources for 3D Printing

To find inspiration and resources for 3D printing your own Lego pieces, explore online communities and forums dedicated to this creative endeavor. These communities provide a wealth of knowledge and support from fellow enthusiasts who are passionate about 3D printing and Lego. Here are three valuable resources you can find in these online communities:

1. Design repositories: There are various websites and platforms where users can find and download ready-to-print Lego designs. These repositories offer a wide range of designs for different Lego pieces and minifigures, allowing you to choose the ones that suit your preferences.

2. Customization tools: Some websites and software offer customization tools that allow users to modify existing Lego designs to fit their preferences. These tools give you the freedom to personalize your Lego creations and make them truly unique.

3. Tutorials and guides: Online tutorials and guides can provide step-by-step instructions and tips for 3D printing Lego pieces and minifigures. These resources cover various topics, including design techniques, printing settings, and post-processing methods, helping you enhance your skills and achieve better results.

In addition to these resources, online communities also offer collaboration opportunities with other enthusiasts and designers. This allows you to collaborate on projects, share ideas, and learn from each other’s experiences. So, dive into these online communities and unlock a world of inspiration and resources for your 3D printing journey.

Introduction to LEGO and 3D Printing

Exploring the intersection of LEGO and 3D printing offers a fascinating glimpse into the world of customizable brick creations. LEGO, a beloved toy brand, has a rich history dating back to its founding in 1932. The company initially used wood and later transitioned to plastic, specifically acrylonitrile butadiene styrene (ABS), which became the primary material for LEGO bricks. ABS is known for its strength, durability, and ability to withstand impact.

In recent years, with the rise of 3D printing technology, enthusiasts have started experimenting with printing LEGO-compatible bricks using various materials, including ABS and polylactic acid (PLA). While ABS remains the preferred choice due to its similarities to the original LEGO material, PLA offers its own advantages, such as being biodegradable and easier to print with.

Lego has also made significant advancements in sustainability, committing to using plant-based materials for their bricks and packaging by 2030. Their dedication to sustainability aligns with the principles of 3D printing, as it allows for the efficient use of materials and reduces waste.

Furthermore, LEGO has a patent that protects the design and functionality of their interlocking brick system. While 3D printing enthusiasts can create custom LEGO-like pieces for personal use, it is important to respect intellectual property rights and not produce or distribute patented LEGO designs without permission.

Injection Molding and 3D Printing Technology

As we delve into the world of injection molding and 3D printing technology, you will discover the fascinating ways in which these manufacturing processes intersect with the creation of custom Lego pieces.

1. Exploring Injection Molding: Injection molding has been the primary method of producing Lego pieces for decades. It involves injecting molten plastic into a mold and allowing it to cool and solidify, resulting in highly precise and consistent parts. This process has allowed Lego to produce millions of pieces with remarkable accuracy.

2. The Sustainability of Injection Molding: While injection molding has been the go-to method for Lego production, there are concerns about its environmental impact due to the use of large amounts of plastic. Lego has recognized these concerns and is committed to sustainability initiatives, such as using plant-based materials for some of their pieces.

3. Enhancing LEGO Designs with 3D Printing: 3D printing technology offers an exciting opportunity to enhance Lego designs. With 3D printing, it becomes possible to create intricate and customized pieces that were previously unachievable through traditional injection molding. This opens up new possibilities for Lego enthusiasts to create unique designs and add personalized touches to their creations.

The convergence of injection molding and 3D printing technology represents an evolution in Lego manufacturing. While injection molding continues to be the primary method for mass production, 3D printing offers a world of customization and creativity. With the future of 3D printing Lego parts on the horizon, we can expect to see even more innovative and personalized Lego creations in the years to come.

Lego’s Relationship With 3D Printing

Lego enthusiasts can explore the exciting relationship between Lego and 3D printing. Lego has made significant advancements in this field and has had a considerable impact on the 3D printing industry. They have collaborated with various 3D printing companies to push the boundaries of creativity and customization. Lego’s approach to copyright and intellectual property in relation to 3D printing has been a topic of interest as well.

| Advancements | Future Plans | Impact on the Industry |

|---|---|---|

| Lego has embraced 3D printing technology to enhance the customization options for Lego enthusiasts. | Lego is constantly exploring new ways to incorporate 3D printing into their product offerings. | Lego’s foray into 3D printing has spurred innovation in the 3D printing industry and has opened up new possibilities for customization. |

| Lego has collaborated with 3D printing companies to create specialized Lego pieces and accessories. | Lego plans to continue collaborating with 3D printing companies to expand their range of custom Lego pieces. | Lego’s collaborations have brought together the expertise of both industries, resulting in unique and high-quality 3D printed Lego products. |

| Lego has taken a proactive approach to address copyright and intellectual property concerns in relation to 3D printing. | Lego is dedicated to protecting their brand and ensuring that their intellectual property rights are respected. | Lego’s approach to copyright and intellectual property has set a precedent for other companies in the 3D printing industry and has helped maintain the integrity of their brand. |

This table provides an overview of Lego’s relationship with 3D printing, detailing their advancements, future plans, and the impact they’ve had on the industry.

As Lego continues to innovate and explore the possibilities of 3D printing, the relationship between Lego and 3D printing will only grow stronger. Lego’s advancements, collaborations, and commitment to protecting their intellectual property have made a significant impact on the 3D printing industry as a whole. Lego enthusiasts can look forward to a future filled with even more exciting and creative possibilities in the world of 3D printed Lego.

Comparison of ABS and PLA LEGO Pieces

When comparing ABS and PLA LEGO pieces, you’ll find differences in durability and compatibility with other LEGO bricks. Here’s a comparison of the two materials:

1. Strength and durability:

– ABS: ABS is known for its strength and durability, making it a popular choice for LEGO pieces. It can withstand more impact and is less likely to break or deform.

– PLA: PLA is a biodegradable material that is less durable compared to ABS. It is more prone to cracking or snapping under stress.

2. Printing techniques:

– ABS: ABS requires a higher printing temperature compared to PLA. It also has a higher shrinkage rate, which can cause warping or cracking during the printing process.

– PLA: PLA is easier to print with because it has a lower printing temperature and minimal shrinkage. It is less likely to warp or crack during the printing process.

3. Compatibility with original LEGO pieces:

– ABS: ABS LEGO pieces are more compatible with original LEGO bricks due to their similar material properties. They fit together more securely and have a smoother connection.

– PLA: PLA LEGO pieces may not fit as well with original LEGO bricks due to slight dimensional differences. They may have a looser connection and require more force to attach.

Cost analysis:

– ABS: ABS filament is generally more expensive than PLA filament.

– PLA: PLA filament is more affordable compared to ABS filament.

Considerations and Limitations of 3D Printing LEGO Parts

When printing LEGO parts using a 3D printer, it is important to consider certain factors and limitations to ensure successful results. One of the key considerations is the precision of 3D printed LEGO pieces. While original LEGO bricks made with injection molding have a precision of 10 micrometers, achieving the same level of precision with standard FFF 3D printers can be challenging. It is worth noting that many makers have successfully printed LEGO parts with varying levels of success.

Another factor to consider is the cost comparison between 3D printed LEGO parts and original ones. While 3D printed parts can be cheaper, it is important to take into account the time spent on print preparation and post-processing. Post-processing techniques such as removing brims and smoothing the surface of the 3D printed parts may be necessary to improve their quality and compatibility with original LEGO pieces.

When using FFF 3D printers, it is important to be aware of their limitations. FFF printers are less accurate than injection molding, so some parts may not fit as well as the original ones. Proper maintenance and calibration of the 3D printer can help achieve better results. Additionally, not all LEGO designs available for free on the internet may be suitable for FFF 3D printing due to small or no clearances.

For specific LEGO parts that are tiny and fragile or require a larger quantity, it may be more suitable to use SLA 3D printers. SLA printers have high accuracy similar to injection molding, making them better suited for these types of parts. However, it is important to consider that SLA-printed LEGO blocks may have difficulty connecting and disconnecting due to friction, which can lead to loosened joints and abrasion.

FFF and SLA 3D Printing for LEGO

If you frequently use a 3D printer for creating LEGO pieces, you may be interested in the differences between FFF and SLA 3D printing technologies. Here are some key points to consider:

1. FFF 3D Printing:

– FFF 3D printing can produce classic LEGO-style and LEGO Duplo-style blocks.

– FFF 3D printers are less accurate than injection molding, so some parts may not fit as well as the original ones.

– Well-maintained and properly calibrated 3D printers achieve better results.

2. SLA 3D Printing:

– SLA printers have high accuracy similar to injection molding.

– SLA-printed LEGO blocks may have difficulty connecting and disconnecting due to friction.

– Friction can lead to loosened joints and abrasion.

3. Precision Limitations and Post Processing Techniques:

– Original LEGO bricks made with injection molding have a precision of 10 micrometers, which is difficult to achieve with standard FFF 3D printers.

– Post-processing techniques, such as smoothing with acetone vapors, can improve the connection between FFF 3D printed parts and original LEGO pieces.

– ASA or ABS materials are recommended for FFF 3D printing, while PLA should not be combined with original LEGO pieces due to potential damage.

Understanding the differences between FFF and SLA 3D printing technologies and the precision limitations can help you make informed decisions when creating custom LEGO pieces. Additionally, utilizing post-processing techniques and compatible materials can enhance the compatibility and quality of your 3D printed LEGO creations.