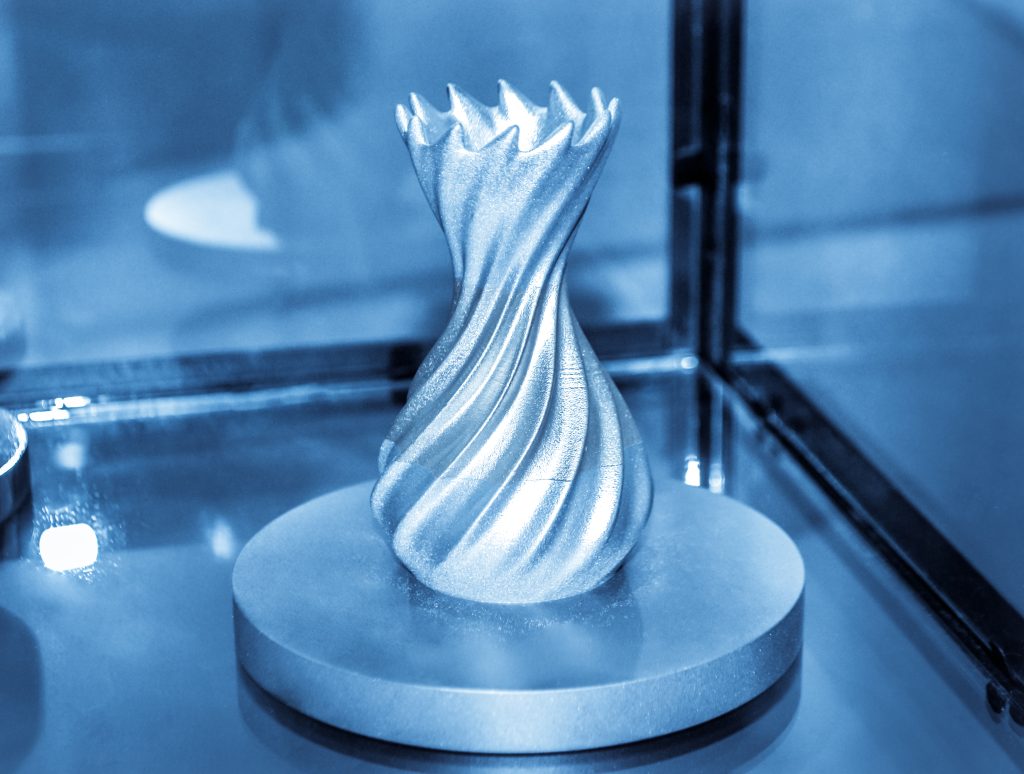

Are you curious about the important role that infill plays in 3D printing? Look no further! In this comprehensive overview, we’ll explore how infill contributes to the strength, weight, and rigidity of printed parts. We’ll discuss different infill patterns like lines, grid, triangles, honeycomb, and cubic and their advantages. Understanding various infill patterns and optimizing print settings will be crucial in achieving optimal results. Get ready to dive into the fascinating world of infill technology and its constant evolution!

Importance of Infill in 3D Printing

Understanding the role of infill is crucial for achieving perfect 3D printing results, as it determines the strength, structure, and weight of your printed part. Infill density optimization plays a significant role in achieving desired mechanical properties. By adjusting the infill density, you can control the solidity of your printed part. Lower infill densities result in lighter parts with reduced material usage and shorter print times. On the other hand, higher infill densities provide stronger parts but require more material and longer print times.

In addition to infill density optimization, selecting the right infill pattern is equally important. Different infill patterns offer varying characteristics in terms of strength, flexibility, weight distribution, and printing time. Commonly used patterns include lines, grid, triangles, honeycomb, and cubic. Each pattern has its own advantages depending on the specific requirements of your printed part.

Furthermore, considering infill material compatibility is essential for successful 3D printing. The chosen infill material should be compatible with both the printer’s capabilities and the intended application of the printed part. Compatibility ensures optimal adhesion between layers and overall structural integrity.

Overall, understanding how to optimize infill density, select appropriate infill patterns, and ensure compatibility with materials are critical factors in achieving high-quality 3D prints with ideal strength-to-weight ratios and structural integrity.

Factors Affecting Infill Selection

Factors such as purpose, desired strength, and material usage influence the choice of infill in 3D printing. When selecting the infill for a 3D printed part, it is important to consider these factors to achieve the desired result. The purpose of the printed object plays a crucial role in determining the appropriate infill percentage. For prototypes or hobbyist creations, lower infill percentages may be preferred to save on time and material costs. However, for functional parts that require strength and durability, higher infill percentages may be necessary.

Another factor to consider is the desired strength of the part. Increasing the infill density improves the overall strength and rigidity of the printed object. On the other hand, lower infill densities can reduce material usage and printing time. Finding the optimal balance between strength and resource utilization is essential.

Material usage is also an important consideration when selecting infill. Higher infill percentages consume more material, resulting in increased cost and longer print times. Balancing material usage with other factors like strength and weight is crucial for achieving optimal results.

In addition to these factors, choosing an appropriate infill pattern is essential for achieving specific characteristics in 3D printed parts. Grid patterns provide stability while optimizing material usage. Honeycomb patterns offer excellent strength-to-weight ratios. Triangular patterns create stable structures within objects.

Types of Infill Patterns

The different types of infill patterns in 3D printing offer varying characteristics and structural properties. When it comes to infill pattern selection, there are several options to choose from. Some common infill shapes include grid, honeycomb, gyroid, triangular, and rectilinear patterns. Each pattern has its own advantages and disadvantages.

The grid infill pattern consists of straight lines arranged in a grid-like structure. It provides good strength while consuming relatively less material. The honeycomb infill pattern features hexagonal cells that offer optimal strength and efficient material usage. The gyroid infill pattern has a unique lattice structure with an excellent strength-to-weight ratio.

The triangular infill pattern uses triangles to create a stable internal structure. It provides good support for the outer walls of the printed part. The rectilinear infill pattern utilizes parallel lines arranged in a grid layout. It is easy to print and offers decent strength.

Infill density adjustment is another important aspect when it comes to 3D printing. Increasing the infill density improves the strength and rigidity of the printed part, but also increases material usage and printing time. On the other hand, reducing the infill density can save on material usage and decrease printing time but may sacrifice some structural integrity.

Adjusting Infill Density

To achieve the desired strength and rigidity of your 3D printed part, you can adjust the infill density to increase or decrease it. The infill density refers to the percentage of solid material inside the part. By adjusting this density, you can optimize the part’s weight, strength, and printing time.

Choosing the optimal infill density is a crucial step in 3D printing. A higher infill density will result in a stronger part but will also increase material usage and print time. On the other hand, a lower infill density will use less material and reduce print time but may sacrifice some strength.

When deciding on the infill density for your part, consider its purpose and load requirements. For functional parts that require high strength, a higher infill density may be necessary. However, for prototypes or non-structural prints where weight reduction is important, a lower infill density may be more suitable.

Keep in mind that adjusting the infill density is just one factor in achieving optimal results. Other parameters such as print speed, layer height, and cooling settings should also be considered to ensure successful prints with the desired characteristics.

Experimentation and testing may be necessary to find the optimal balance between infill density, print time, and part strength for your specific application.

Advanced Infill Techniques

When looking to enhance the strength of your 3D printed parts, consider exploring advanced infill techniques such as variable density or incorporating structural reinforcements. Variable density infill allows you to adjust the infill density in different sections of the object, giving you more control over its strength and weight distribution. By increasing the infill density in areas that require additional support, you can strengthen those specific regions without adding unnecessary weight to the rest of the part.

Another option is infill with structural reinforcement. This involves adding ribs or supports within the infill structure to provide additional strength and rigidity to the part. These reinforcements act as internal frameworks, improving the overall structural integrity of your 3D printed object.

Additionally, you may want to consider using flexible materials for your infill. Infill with flexible materials can create objects with varying levels of flexibility and stiffness, allowing you to customize the mechanical properties of your parts according to your specific requirements.