In the world of 3D printing, you need to understand the materials that make it all possible. From polymer plastics like PLA and ABS to innovative options like wood, metals, composites, and even concrete – the possibilities are endless. These materials offer unique properties for different applications, whether it’s creating lightweight car parts or constructing affordable housing. With efficient material usage and cost-effective prototyping, 3D printing is revolutionizing industries like manufacturing and healthcare. Get ready to dive into the world of 3D printing materials and discover what makes them so essential.

Overview of 3D Printing Materials

Plastic materials, powders, and resins are the main types of materials used in 3D printing. Advancements in material technology have led to a wide range of options for creating three-dimensional objects. Plastics, such as polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polyvinyl alcohol plastic (PVA), and polycarbonate (PC), are commonly used due to their versatility and affordability.

Sustainability is also a key consideration in 3D printing. PLA, for example, is made from renewable resources like cornstarch or sugarcane, making it biodegradable and environmentally friendly. Additionally, advancements in recycling technologies allow for the reuse of plastic waste generated during the printing process.

Emerging materials for 3D printing include powders and resins. Powders like nylon and polyamide offer durability and flexibility, making them suitable for aerospace and industrial machinery components. Resins, on the other hand, provide high levels of detail and smooth finishes. Different types of resins are available including standard resins for general use, engineering-grade resins for strength and durability, and biocompatible resins for medical applications.

The impact of material properties on print quality cannot be overstated. Factors such as melting temperature, viscosity, elasticity, and adhesion can affect the final outcome of a printed object. Understanding these properties allows designers to choose the right material that will result in accurate dimensions, structural integrity, and desired surface finish.

Exploring Plastic 3D Printing Materials and Processes

Thermoplastics and thermosetting plastics have different characteristics when it comes to 3D printing. Thermoplastics are materials that can be melted and reformed multiple times without undergoing any significant chemical change. This makes them ideal for 3D printing processes such as Fused Deposition Modeling (FDM), where the material is heated and extruded through a nozzle to create the desired shape layer by layer.

On the other hand, thermosetting plastics undergo a chemical reaction during the curing process, which irreversibly hardens the material. This makes them suitable for processes like Stereolithography (SLA), where liquid resin is cured using UV light to form solid objects with high levels of detail and smooth finishes.

Plastic 3D printing has several advantages in various industries. The ability to use different types of plastic materials allows for customization, cost-effectiveness, and the creation of complex shapes not achievable with traditional methods. Recent developments in plastic 3D printing have led to advancements in manufacturing, healthcare, and even construction industries.

Understanding Metal 3D Printing

When exploring metal 3D printing, you’ll discover various printers and materials that offer unique advantages in terms of strength, cost savings, and applications in industries like healthcare and jewelry design. Metal 3D printing has gained popularity due to its ability to create complex geometries with high precision. One of the key advantages of metal 3D printing is its exceptional strength, making it suitable for manufacturing parts that require durability and reliability. Additionally, metal 3D printing allows for cost savings by reducing material waste compared to traditional manufacturing methods. This technology also enables the production of customized medical implants, such as orthopedic implants and dental crowns.

However, there are challenges in metal 3D printing that need to be addressed. One challenge is the high cost associated with equipment and materials. Another challenge is achieving consistent quality throughout the entire print process, including maintaining proper metal powder distribution and minimizing defects.

In terms of future developments in metal 3D printing, researchers are working on improving the speed and scalability of the process while maintaining high-quality output. There is also ongoing research on developing new materials with enhanced properties for specific applications.

Overall, metal 3D printing offers immense potential in various industries due to its unique advantages such as strength, cost savings, and customization capabilities. With continued advancements in technology and materials, we can expect even greater possibilities for innovation in this field.

Choosing the Right 3D Printing Material

One important factor to consider when selecting the appropriate 3D printing material is its compatibility with the desired application and performance requirements. For example, metal 3D printing offers advantages such as cost savings, volume reduction, and applications in healthcare and jewelry design. On the other hand, resin materials have their own considerations, including different types of resins offering varying levels of speed and precision.

The impact of 3D printing on the construction industry cannot be overlooked. Additive practices in construction have advanced to the point where updated building codes are being implemented. This innovative technology has the potential to address affordable housing issues and offer more efficient construction methods.

In terms of plastic 3D printing materials, there are numerous innovative applications. Plastics allow for cost-effective prototyping and faster iteration while also enabling customization and print-on-demand capabilities. Additionally, plastic 3D printing offers the ability to create complex shapes that would not be achievable with traditional manufacturing methods.

Overall, choosing the right 3D printing material requires careful consideration of factors such as compatibility with application requirements, performance needs, and specific industry impacts. By understanding these considerations and exploring the advantages of different materials like metal or resin-based plastics, you can make informed decisions that will optimize your 3D printing projects for success in various industries.

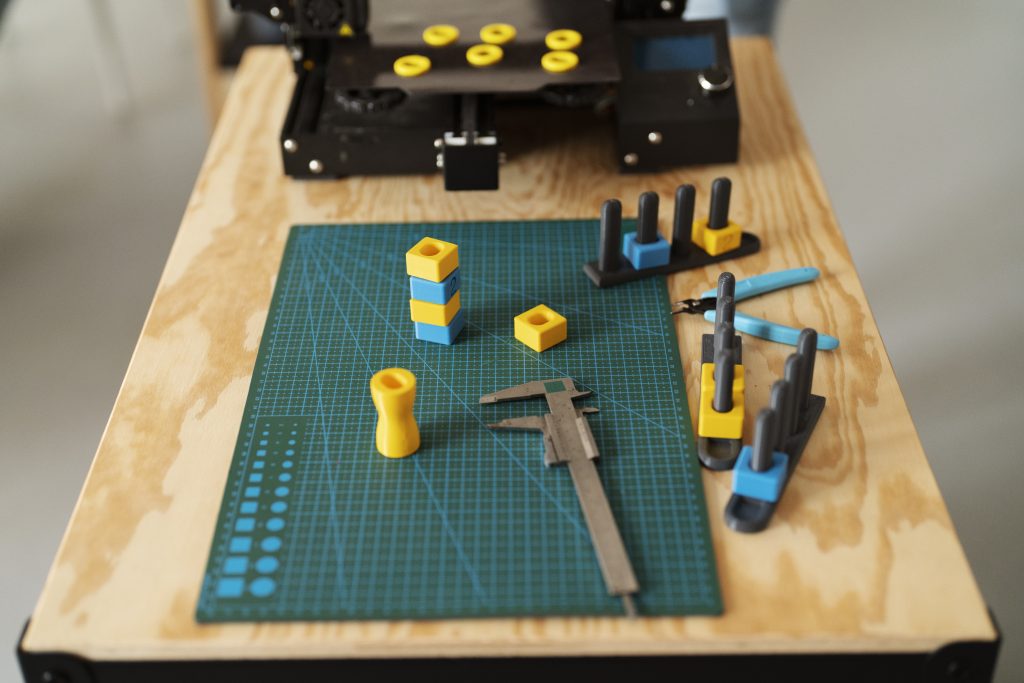

Basic 3D Printer Supplies for Material Handling

To handle materials in 3D printing, basic supplies like storage containers, adhesives, and ventilation equipment are essential. Proper storage of 3D printer filament is crucial to maintain its quality and prevent moisture absorption. Use airtight containers with desiccant packets to keep the filaments dry and free from contaminants. When selecting adhesives for first layer adhesion or assembly of printed parts, consider factors such as material compatibility, strength requirements, and ease of use. Ventilation safety measures are important to protect yourself from potentially harmful fumes emitted during printing. Ensure adequate ventilation in your workspace or use an enclosure with built-in air filtration systems. Nozzle maintenance and cleaning are necessary for consistent print quality. Regularly check for clogs or buildup in the nozzle and use appropriate tools like nozzle cleaning kits or unclogging agents to remove any obstructions. Cleaning the nozzle before each print helps ensure smooth filament flow and prevents defects in your prints. By properly handling materials and using the right supplies, you can enhance your 3D printing experience and achieve optimal results.

Types of Printing Material in 3D Printing

Choose the right printing material for your 3D printer by considering factors such as plastic, powders, resins, metal, and carbon fiber. When it comes to 3D printing materials, there are various options available with their own advantages and limitations.

Plastic is the most common material used in 3D printing. It is widely accessible and affordable. Filaments like PLA, ABS, and PETG are popular choices for plastic 3D printing due to their ease of use and versatility. However, plastic materials may not be suitable for applications that require high strength or heat resistance.

Metal 3D printing offers unique advantages over plastic materials. Metal parts produced through additive manufacturing have superior strength and durability compared to traditional manufacturing methods. This makes metal 3D printing ideal for industries such as aerospace and healthcare where precision and reliability are crucial.

On the other hand, resin-based 3D printing has its limitations. While resin printers can achieve high levels of detail and smooth finishes, they tend to be slower than other types of printers. Additionally, resin materials can be more expensive and have limited color options compared to plastics.

Emerging materials in 3D printing include composites like carbon fiber. Carbon fiber offers a combination of strength and lightness which can revolutionize industries such as automotive and aerospace.