Are you curious about 3D printing and how it’s reshaping industries?

In this ultimate guide, we’ll take you on a journey to explore the basics, the process, and the numerous applications of this groundbreaking technology.

From consumer products to healthcare and even construction, 3D printing is revolutionizing the way we live, work, and play.

So get ready to dive into the world of 3D printing and discover its incredible potential.

The Basics of 3D Printing

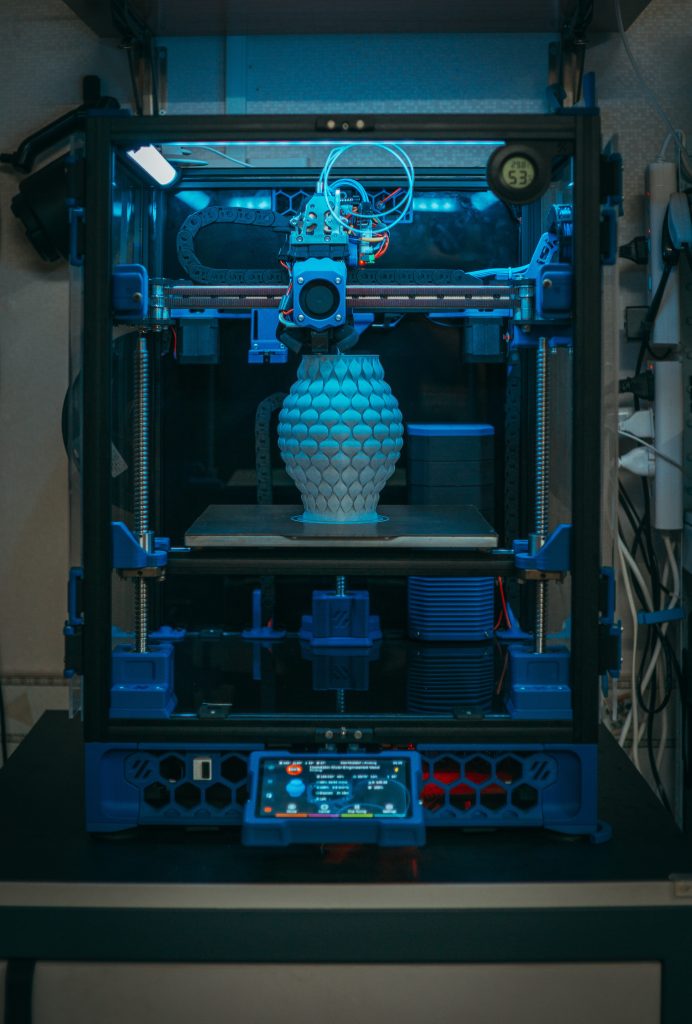

Now let’s dive into the basics of 3D printing and understand how it works.

3D printing offers a wide range of benefits. It has the potential to revolutionize industries and change the way we live, work, and play in the future.

In education, 3D printing provides a hands-on learning experience, allowing students to bring their ideas to life and explore complex concepts in a tangible way. It promotes creativity, problem-solving skills, and critical thinking.

The future of 3D printing looks promising, with the technology rapidly advancing and becoming more accessible. As it continues to evolve, we can expect to see even more innovative applications and advancements in various fields, from healthcare to consumer products.

3D printing is truly shaping the world we live in.

Understanding the 3D Printing Process

The 3D printing process involves using various software tools, such as Tinkercad, to create printable files that are then sliced into layers using slicing software.

Advancements in 3D printing technology have led to significant improvements in the speed, accuracy, and range of materials that can be used for printing. However, there are still challenges and limitations that need to be addressed.

One challenge is the high cost of 3D printers and materials, which limits accessibility for many individuals and businesses. Another challenge is the limited range of materials that can be used for printing, although there has been progress in developing new materials such as metals and ceramics.

Looking towards the future, there are promising prospects and trends in 3D printing, including the potential for on-demand manufacturing, customization, and even the ability to print living tissues and organs.

As technology continues to advance, we can expect to see even more exciting developments in the field of 3D printing.

Exploring the Applications of 3D Printing

You can explore a wide range of applications for 3D printing in various industries, including consumer products, healthcare, construction, and more.

In the world of fashion, 3D printing is revolutionizing the way garments and accessories are created. Designers can now easily bring their intricate and unique creations to life with the help of this technology.

Additionally, 3D printing in art allows artists to push the boundaries of their creativity by producing complex and detailed sculptures and installations. It provides them with a new medium to express their artistic vision.

In the field of education, 3D printing is enhancing the learning experience by allowing students to physically interact with objects they have designed. It promotes hands-on learning and encourages innovation and problem-solving skills.

3D Printing in Construction

3D printed houses are now commercially available, allowing for quick and repeatable laying down of concrete layers in construction. The advantages of 3D printing in construction are numerous. It enables faster construction times, reduces labor costs, and allows for more complex and intricate designs.

Additionally, 3D printing in construction reduces waste and environmental impact by using only the necessary amount of materials. However, there are challenges in implementing this technology. The high initial costs of 3D printing equipment and the need for skilled operators are some of the obstacles that need to be overcome.

Despite these challenges, the future prospects of 3D printing in construction are promising. As the technology continues to advance and become more affordable, we can expect to see increased adoption and innovation in the construction industry.

3D Printing in Consumer Products

Adidas has revolutionized the footwear industry by incorporating fully 3D printed midsoles in their 4D range. This advancement in 3D printing technology has also made its way into other consumer products, including fashion, home decor, and consumer electronics.

In the world of fashion, 3D printing allows designers to create intricate and unique designs that were once thought impossible. From clothing to accessories, 3D printing has opened up a whole new world of possibilities.

In home decor, 3D printing allows for the creation of custom furniture pieces, decorative items, and even entire houses.

And in consumer electronics, 3D printing is being used to create personalized cases, headphones, and other tech accessories.

With the advancements in 3D printing technology, the possibilities for consumer products are endless.

3D Printing in Healthcare

Now, let’s explore the fascinating world of 3D printing in healthcare. Imagine a future where prosthetics are custom-made to perfectly fit your body, surgical tools are specifically designed for each patient, and pharmaceuticals are personalized to your unique needs. With 3D printing, this future is becoming a reality.

One of the remarkable applications of 3D printing in healthcare is the production of 3D printed prosthetics. These prosthetics are not only tailored to the individual’s anatomy but also significantly cheaper and faster to produce compared to traditional methods. Moreover, 3D printing enables the creation of intricate designs that enhance functionality and comfort.

Another area where 3D printing is making a significant impact is in the production of surgical tools. Surgeons can now have access to customized tools that are specifically designed for each patient’s unique anatomy. This improves surgical precision and reduces the risk of complications during procedures.

Additionally, 3D printing is revolutionizing the pharmaceutical industry. With this technology, it is possible to create complex drug formulations with precise dosages tailored to individual patients. This opens up new possibilities for personalized medicine and more effective treatments.

Materials Used in 3D Printing

Thermoplastics, metals, resins, and ceramics are some of the materials commonly used in 3D printing. These materials offer numerous benefits in the world of additive manufacturing. One of the main advantages is the ability to create complex geometries and intricate designs that are difficult to achieve with traditional manufacturing methods. Additionally, 3D printing materials allow for customization and personalization, making it easier to produce unique and tailored products.

As technology continues to advance, there are also emerging materials in 3D printing. For example, researchers are exploring the use of biodegradable and sustainable materials to reduce the environmental impact of 3D printing. Furthermore, advancements in nanotechnology are paving the way for the development of high-performance materials with enhanced properties such as strength, flexibility, and conductivity.

Looking ahead, future trends in 3D printing materials include the incorporation of smart and functional materials. This includes materials that can change shape or color in response to external stimuli, as well as those with built-in sensors or electronics. These advancements open up new possibilities for creating innovative products and applications in industries such as healthcare, aerospace, and consumer goods.

A Brief History of 3D Printing Technologies

Chuck Hull, the founder of 3D Systems, introduced stereolithography in 1984, a technology that allows parts to be created through photopolymerization and selective curing. This marked the beginning of the evolution of 3D printing and the advancements in additive manufacturing.

Over the years, 3D printing has made a significant impact on various industries. It has revolutionized the way products are designed, prototyped, and manufactured. With 3D printing, industries have experienced reduced lead times, cost savings, and increased customization options.

Aerospace and automotive industries have embraced 3D printing for creating complex parts and reducing material wastage. In the medical field, 3D printing has enabled the production of patient-specific implants and prosthetics.

The impact of 3D printing on industries is undeniable, and it continues to shape the future of manufacturing.